Hello,

I'm new to the IET community so I'm not exactly sure if I'm going about using the resources correctly.

I have come across a problem in one of my projects some weeks ago so I would love to hear what more experienced and knowledgeable people in the industry think.

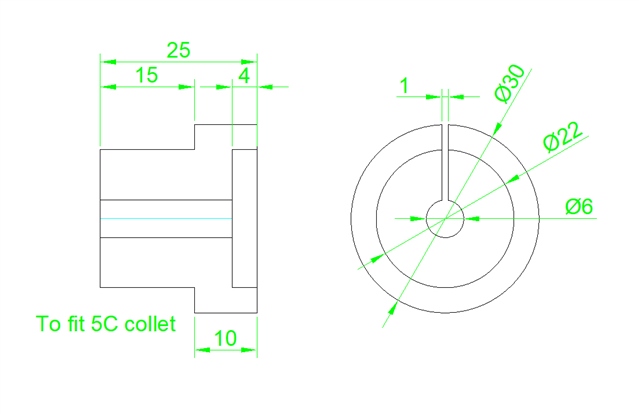

How would you grip a small round steel part with a height of only 3-4 mm and diameter of app. 22 mm.

Holding the part is not the essence of the problem. The part has to be able to withstand torqueing another part into it at up to 40 Nm.

The solution I used worked semi-well for the purpose but the grip is definitely not strong enough because the parts are coming out damaged more often than not.