Sparkingchip:

Or you can spend a considerable amount of money on a top end EV charger that can possibly just be connected into a spare way in your existing consumer unit and charge the EV one hell of a lot faster.

Chris Pearson:

Sparkingchip:

Or you can spend a considerable amount of money on a top end EV charger that can possibly just be connected into a spare way in your existing consumer unit and charge the EV one hell of a lot faster.Oh dear! They don't seem to understand the difference between the capacity of the fuse holder and the rating of the fuse within it; and no mention of the earthing arrangement.

Simon Barker:

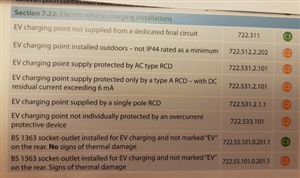

I'm still wondering why it is that we've been running boats, caravans, burger vans, garden tools and pressure washers from outdoor sockets for years, and all it needs is a single RCD protecting the circuit.

But the moment someone wants to charge an EV, it needs some box full of magical pixie dust, or everyone who touches the vehicle when it's on charge will instantly be electrocuted. ?

How can it be so difficult?

Edit: OK, so I think caravans shouldn't be on TN-C-S. So just TT the supply. If the EV charge point is outdoors, is that too hard?

Spend £70 or less on a EV looky likey consisting of a labeled 13-amp single socket and a near useless RCBO in a plastic box and you will need to spend a couple of hundred quid on a consumer unit with a new consumer unit with a type B 30 mA DP RCD in it

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site