I don't think that I have seen this in here before, but these batteries came up in a motoring forum.

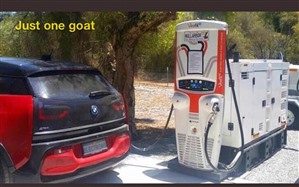

The claim to charge an EV all the way in 5 min seems to be entirely spurious - all that they have managed so far is a moped, but even if the batteries existed, how would they be charged?

Here is my back-of-a-fag-packet calculation. An average EV will do 4 - 5 miles per kWh; let's be conservative and say 4. So with a range of 300 miles between charges, that requires 75 kWh. Delivered over 1/12 hour that requires 900 kW. So in round terms, that is one 1 MVA transformer per EVCP. Could be useful on a motorway, but I cannot see the point elsewhere. Even then, very few journeys in UK are over 300 miles. Both Edinburgh and Land's End are closer to Birmingham than that.

900 kW at 48 V DC is almost 20,000 amps. What sort of connexion is envisaged?