Hi,

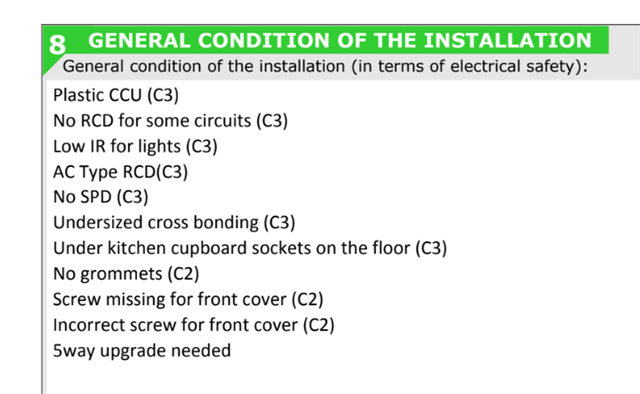

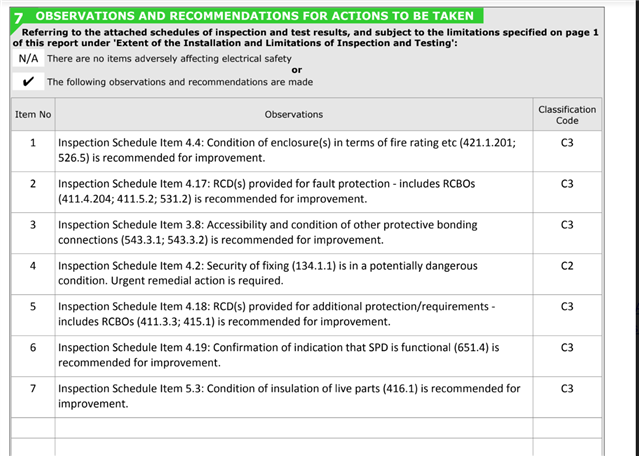

I have done an EICR recently. I got C2 for "4.2 security of fixing (134.1.1.)"

Which I felt is bit unfair. They are trying to charge me £750 + VAT to fix the issue (repace with new consumer unit).

I felt they are trying to put me in a panic mode and upsale to me.

Could I get a second opinion on if the item is code worthly?

The consumer unit is located in storage cupboard.

I would appreciate if you could provide an extract of the related section on the regulation, to provide justification.