Hi everyone,

The packaging and design of electric motors has been tested, unsurprisingly, in recent years as the rate of vehicle electrification has accelerated. Having been dismissed as overly expensive and dynamically problematic for most automotive applications, they are increasingly focusing on EV use. Car developers recognize that hub motors offer advantages - especially in all-wheel drive applications. At the same time, hub motors tend to prefer the packaging advantages offered by axial flow motor designs.

Inside the engine

The first prototypes of the designed electronic axis were built and tested in an expandable manner. "You can even take the motors back out and replace them with the axial flux technology and return it to the hub".

The various propulsion topologies described above apply to both electric vehicles and hybrid serial vehicles in which the combustion engine has no mechanical connection to the drive shaft and only

One generator drives.

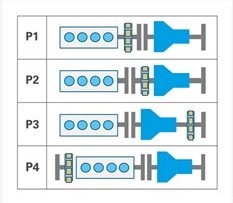

Parallel hybrids that are next to an electronic motor also have a direct connection between the internal combustion engine and the propulsion shaft, these technologies are included in the arrangement of split axles, the propulsion technology P4 can also be found (see diagram below)

The combustion engine drives one of the two axles and the electric propulsion vehicle drives the other axle. Examples of this technology are the PHEV BMW X1 25e and PEUGEOT 3008 HYBRID4 vehicles, in which the rear axle is driven solely by an electric motor.