. . but I do have an ancient compact tractor!

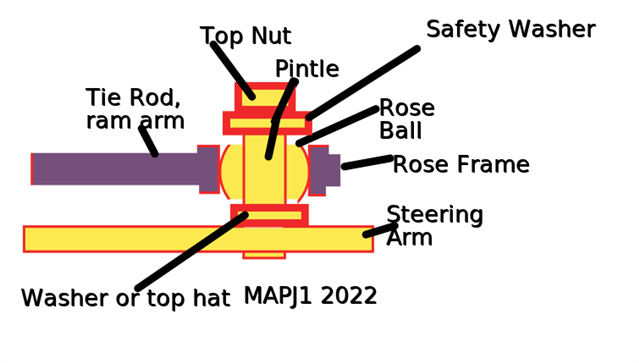

The power steering ram is connected to the steering arm with the usual ball coupling but with a straight M12 bolt rather than the tapered bolt that you generally find on track rod ends.

Unfortunately the M12 hole in the steering arm has become ovalled causing excessive play.

The steering arm is part of the casting for the front hub and 4WD system and cannot be removed so any repair will have to be in situ.

My first thoughts were to try and drill out and then ream the oval to 18mm and insert a new 12mm id bush but I was wondering if the collective brains on here had a better solution.

Thanks. G