Hi all

Something that I have always wondered about since I started doing electrical work.

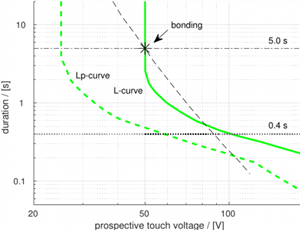

The 0.4 and 5 second disconnection times. 0.4 makes sense as it is quick.

However 5 seconds still seems a long time for exposed conductive parts to remain live. When I first started, lighting circuits had a 5s time.

Now it's 0.4 for all circuits feeding socket outlets up to 63A but only for fixed equipment up to 32A. So any equipment over 32A can be 5s.

The reason given in collage was that it was portable equipment that can be picked up and gripped but fixed equipment can be pulled away from.

Previously, in 16th ed regs, the 0.4 was for socket outlets and circuits supplying equipment that can be hand held.

However, 5 seconds still seems a long time for exposed metalwork to be live. I know with a low impedance earth the voltage will be lower, but still.

The other thing is that even a distribution circuit that can have 5s dis time, on an earth fault, say in an armoured cable, all earthed metalwork can be live for the full 5 seconds, even hand held equipment on circuits with a 0.4s dis time. I realise that if the fault was on the actual item of equipment itself the voltage would be higher.

Any equipment, though, above 32A can still have a 5s dis time. I come across fixed equipment all the time that is above 32A. This equipment quite often has parts of it that can actually be gripped. When the body has electricity passing though it the muscles contract so it may be hard to pull away.

I've seen a video of three men pushing a tower hitting an overhead HV line. all three dropped down but their hands still gripped the scaffold poles.

I know were dealing with LV but the muscles still react the same.

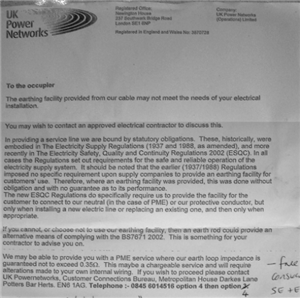

Even showers could once have a 5s dis time and the only thing that has changed that is the regs for RCDs in rooms containing a bath or shower. It's still on a circuit that, without the RCD, allows 5s.

The fact that the regs have tightened up of what circuits can have 5s dis times shows that there is still a danger on 5s. Otherwise, why change them to 0.4s.

Any thoughts?