I am looking at installing around 21 LED Lighting Columns to a Car Park. It states on the product data sheets that the Lamp Heads are 890mA / 68watts each (I think the 890mA refers to the output current of the driver and not the input current which will be nominally P/V excluding the efficiency of the driver). I have checked all the volt drops and cable calcs which have calculated out at 6mm 3core SWA buried underground. I am splitting the Lighting columns up into circuits and I would prefer to have 7 columns on each circuit. From the information provided on the data sheet it states that the inrush current is 57Amps per column which does seem a little high considering such a small load. This would mean when I select a suitable Overcurrent Device from BS7671 Time Current Curve Charts to withstand the 57Amps x 7 Columns = 399Amps inrush current. Full Load Current being 68Watts x 7 = 476Watts equates to around 2Amps. As 57Amps inrush is quoted (sum of + 399Amps) for the one Lighting Column then the following is concluded:

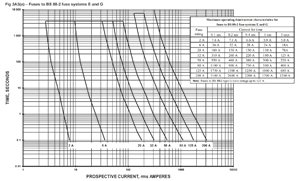

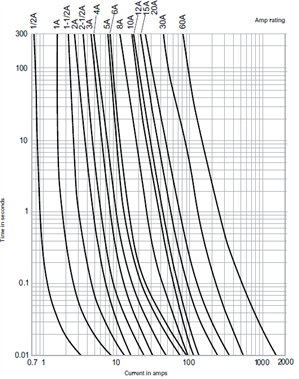

Assuming a 10Amp Type B – this would be not suitable as this device can only withstand 50Amps up to 5 Seconds so it will cause an instantaneous trip (this would normally be the device i would choose as default)

Assuming a 10Amp Type C – Suitable for a max of 1 Lighting Column as this device can only withstand 100Amps up to 5 Seconds so it will cause an instantaneous trip with 2 Lighting Columns wired on the one circuit

Assuming a 10Amp Type D - Suitable but only for a max of 3 Lighting Columns as this device can only withstand 200Amps up to 0.4 Seconds and withstand up to 100Amps over 5 Seconds so it will instantaneously trip with more than 3 Lighting Columns wired on the one circuit (i would usually use Type D only on motor circuits and not the usual device of choice for protecting Lighting Circuits)

Deduced from the data sheet and if all is correct, we could only wire a maximum of 3no Lighting Columns per circuit but this using a Type D Overcurrent Device to be sure no tripping will occur during initial spike. This has confused me slightly because I have never seen such high inrush currents like this for such small LED Lighting Loads.

I wondered if any Electrical Designers/Electricians had queried this before with manufacturers and also whether i am missing something. One would expect you could have 7 Columns per circuit as such a small load of 2Amps but the inrush would surely take out the protective device ?