This suppressor was fitted to my lathe on the load side of the VSD. Something went wrong when I was parting off the other day - the tool dug in and the motor stalled - and now it is running roughly. Back to square 1!

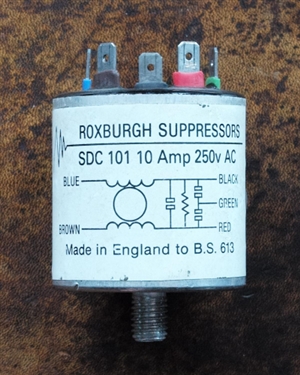

In an attempt to determine whether the VSD has been damaged, I tried connecting another motor, but I was unable to demonstrate protective earth continuity. The cable from the green terminal on the suppressor goes to the motor's earth terminal. I expected that the case of the suppressor would be the supply side of the PE, but apparently not. So with the suppressor fitted there is no PE to the motor, which I find a little disconcerting.

FWIW, the capacitance between red and black is about 0.5 µF, the resistance is 470 kΩ, and the capacitance between each of red and black to green is 9 nF.

Would somebody kindly explain whether this is safe please?