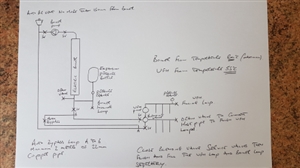

I am being told that wet UFH only needs one pump located on the UFH manifold and UFH circuits.

My understanding is that it needs two pumps, one for the boiler circuit and one for the UFH circuits as they are two distinct circuits.

Seeing as you are all experts on circuit arrangements, tell me if the UFH manifold pump can circulate the water through the boiler without a boiler circuit pump installed?