Three weeks ago I asked about Bonding Gas & Water pipes and whether it was acceptable/permissible for the earth bonding conductor to be a single 10 mm² green/yellow from the consumer unit to go to say the water 351 earth clamp, looped around the screw and then to the gas 351 without cutting the cable, so that it is one continuous length. (Or if not looped around the crew, for a bare section to be opened up 3 strands and 4 strands and the screw fitted between?) https://communities.theiet.org/discussions/viewtopic/1037/28142?post_id=160255#p160255

Since then, I have been involved in the splitting of the water supply to replace lead pipe through the common meter to the two properties.

The original property was basically a village hall with an attached house for a caretaker. The water supply, via a single meter in lead pipe came into the village hall (at the front) and beneath the floor was split. One section went to the rear of the building where it entered as a lead riser to the stop tap where it became copper. A 351 on the 15mm copper is connected via 10 mm² green/yellow to the earth block in the meter cupboard. Three phase TNS with a conductor from the PILC to the earth block. A second 10 mm² green/yellow from the copper gas pipe at the meter outlet is connected to the earth block.

A new MDPE water pipe has been installed which comes up outside to be connected to the existing meter and to the existing 15mm copper water pipe which is located near to the gas meter and 351.

Similarly, for the caretaker's house, a new MDPE water pipe has been moled in to connect to an internal cold 15mm water pipe adjacent to the combi boiler. Currently there is a 10 mm² green/yellow between the house earth block adjacent to the house incoming PILC cable and the gas meter outlet pipe which is the other side of the wall to the combi boiler. This 10 mm² green/yellow is quite slack and my intention is to cut a section of g/y insulation off this cable and connect to a 351 where the MDPE connects.

The existing water supply into the house is at the other end of the lead pipe which beneath the village hall floor. Again at the stop tap there is a 351 with10 mm² green/yellow to the house earth block.

So, a couple of questions if I may.

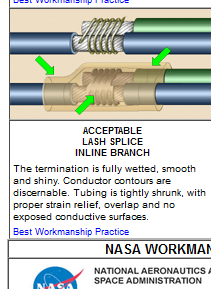

1. There is insufficient slack on the village hall 10 mm² green/yellow to the 351 on the gas pipe to reach a 351 located on the nearby 15mm copper water pipe. Can the existing 10 mm² green/yellow to the gas pipe be connected into a 4-way earth block such as a https://www.screwfix.com/p/4-way-earth-block/12386 and the two 351s connected to this earth block using two 10 mm²?

I am a little wary, since a NAPIT registered friend, tells me that there HAS to be separate 10 mm² green/yellows for the gas and water pipes.

2. Can the original G/Y and 351 remain on the existing incoming water pipes in village hall and house?

Many thanks.

Clive