ProMbrooke:

I like to think this also fits the 3 strikes rule: Both the inner cores, outer covering and RCD must fail for a lethal hazard to exist.

A "single strike" sadly: vacuum cleaner falls downstairs when plugged in, or lawnmower severs mains flex (OCPD doesn't always operate here due to the speed of the blade)

ProMbrooke:gkenyon:ProMbrooke:

Thats where CPCs come in, in that they would cause the fuse or MCB to open in 0.2 seconds or less.Doesn't that happen anyway ... in TN systems where the loop impedance ensures operation in 0.1 s?

The issue being, that, in TN-S systems (no RCD), you're limited in circuit length with Type C mcb's.

Also, interested where 25 V comes into the equation here? To do that, you've got to oversize the cpc, not undersize it ... and even then, may not be possible in TN-S due to the effect of the distributor's cpc ?

It does, but going by table 41.1 we are allowed a loop Z high enough to cause 0.4 seconds disconnection.

Type A, B, or C MCBs, fuses, or the like you are always limited in circuit length be it voltage drop or should the RCD become inoperative.

25 volts is the highest touch voltage under infinite time allowed by the IEC in wet locations according to Table C.1 in IEC 61200-413. Where higher touch voltage are found, disconnection is required. At 125 volts 0.17 seconds is required. With a reduced size CPC, even faster times are required.

IEC 61200-413 is now inactive. It's not a current standard.

As I've said repeatedly, you'd need to refer to something more up-to-date.

Latest versions of IEC 61140 and IEC 60479 series.

gkenyon:ProMbrooke:gkenyon:ProMbrooke:

Thats where CPCs come in, in that they would cause the fuse or MCB to open in 0.2 seconds or less.Doesn't that happen anyway ... in TN systems where the loop impedance ensures operation in 0.1 s?

The issue being, that, in TN-S systems (no RCD), you're limited in circuit length with Type C mcb's.

Also, interested where 25 V comes into the equation here? To do that, you've got to oversize the cpc, not undersize it ... and even then, may not be possible in TN-S due to the effect of the distributor's cpc ?

It does, but going by table 41.1 we are allowed a loop Z high enough to cause 0.4 seconds disconnection.

Type A, B, or C MCBs, fuses, or the like you are always limited in circuit length be it voltage drop or should the RCD become inoperative.

25 volts is the highest touch voltage under infinite time allowed by the IEC in wet locations according to Table C.1 in IEC 61200-413. Where higher touch voltage are found, disconnection is required. At 125 volts 0.17 seconds is required. With a reduced size CPC, even faster times are required.

IEC 61200-413 is now inactive. It's not a current standard.

As I've said repeatedly, you'd need to refer to something more up-to-date.

Latest versions of IEC 61140 and IEC 60479 series.

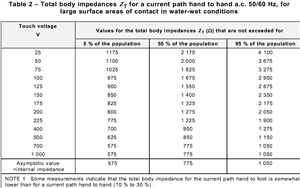

IEC 60479 still gives similar results. 30% decrease from 900 is 630 ohms. So assuming 630 ohms vs 500 ohms take us to around 0.2 seconds vs 0.17 seconds in the old standard.

gkenyon:ProMbrooke:

I like to think this also fits the 3 strikes rule: Both the inner cores, outer covering and RCD must fail for a lethal hazard to exist.

A "single strike" sadly: vacuum cleaner falls downstairs when plugged in, or lawnmower severs mains flex (OCPD doesn't always operate here due to the speed of the blade)

In my experience the cord does not break in the vaccuum cleaner incident. But if it did, you still have strike two of reaching over to touch a severed cord which is less likely given simply picking up a cord one thought to be safe but has a fray in it.

gkenyon:ProMbrooke:Zoomup:Not if the cable is just two core they wouldn't. Or if the appliance is all insulated=Class 2.

Z.Right, where you would have a double insulated tool, which is not capable of becoming live ie made of plastic.

I think the issue Z is highlighting is that Class II products (and perhaps tools - but "live working" tools are not a measure for protection against shock etc. alone) is that they can get broken when being used. Under those circumstances, a single fault outside the provisions of the product standard (broken appliance casing, or damaged flexible cable, for example) exposes ordinary persons directly to live conductors ??

That would be an issue with the listing standard for the tool/appliance vs BS7671 needing to over reach into a product listing IMO.

But I do get your point and I think there is where standards for appliances should be such that such a scenerio is not likely. Think of apple chargers that used to fall apart when unplugged- now they can not be torn apart by reverse engineering.

ProMbrooke:gkenyon:ProMbrooke:gkenyon:ProMbrooke:

Thats where CPCs come in, in that they would cause the fuse or MCB to open in 0.2 seconds or less.Doesn't that happen anyway ... in TN systems where the loop impedance ensures operation in 0.1 s?

The issue being, that, in TN-S systems (no RCD), you're limited in circuit length with Type C mcb's.

Also, interested where 25 V comes into the equation here? To do that, you've got to oversize the cpc, not undersize it ... and even then, may not be possible in TN-S due to the effect of the distributor's cpc ?

It does, but going by table 41.1 we are allowed a loop Z high enough to cause 0.4 seconds disconnection.

Type A, B, or C MCBs, fuses, or the like you are always limited in circuit length be it voltage drop or should the RCD become inoperative.

25 volts is the highest touch voltage under infinite time allowed by the IEC in wet locations according to Table C.1 in IEC 61200-413. Where higher touch voltage are found, disconnection is required. At 125 volts 0.17 seconds is required. With a reduced size CPC, even faster times are required.

IEC 61200-413 is now inactive. It's not a current standard.

As I've said repeatedly, you'd need to refer to something more up-to-date.

Latest versions of IEC 61140 and IEC 60479 series.

IEC 60479 still gives similar results. 30% decrease from 900 is 630 ohms. So assuming 630 ohms vs 500 ohms take us to around 0.2 seconds vs 0.17 seconds in the old standard.

But that's for large contact area ... and hand to hand.

You'd probably be more realistic looking at small or medium contact area, hand-to-foot.

What about saltwater-wet conditions?

Why do all conditions need to consider water-wet?

And finally ... if you do have a serious concern ... you're not taking children into account, and at least 10 % of the population (but then again, IEC 60479 doesn't full stop really).

gkenyon:ProMbrooke:gkenyon:ProMbrooke:gkenyon:ProMbrooke:

Thats where CPCs come in, in that they would cause the fuse or MCB to open in 0.2 seconds or less.Doesn't that happen anyway ... in TN systems where the loop impedance ensures operation in 0.1 s?

The issue being, that, in TN-S systems (no RCD), you're limited in circuit length with Type C mcb's.

Also, interested where 25 V comes into the equation here? To do that, you've got to oversize the cpc, not undersize it ... and even then, may not be possible in TN-S due to the effect of the distributor's cpc ?

It does, but going by table 41.1 we are allowed a loop Z high enough to cause 0.4 seconds disconnection.

Type A, B, or C MCBs, fuses, or the like you are always limited in circuit length be it voltage drop or should the RCD become inoperative.

25 volts is the highest touch voltage under infinite time allowed by the IEC in wet locations according to Table C.1 in IEC 61200-413. Where higher touch voltage are found, disconnection is required. At 125 volts 0.17 seconds is required. With a reduced size CPC, even faster times are required.

IEC 61200-413 is now inactive. It's not a current standard.

As I've said repeatedly, you'd need to refer to something more up-to-date.

Latest versions of IEC 61140 and IEC 60479 series.

IEC 60479 still gives similar results. 30% decrease from 900 is 630 ohms. So assuming 630 ohms vs 500 ohms take us to around 0.2 seconds vs 0.17 seconds in the old standard.But that's for large contact area ... and hand to hand.

You'd probably be more realistic looking at small or medium contact area, hand-to-foot.

What about saltwater-wet conditions?

Why do all conditions need to consider water-wet?

And finally ... if you do have a serious concern ... you're not taking children into account, and at least 10 % of the population (but then again, IEC 60479 doesn't full stop really).

A handle on a fridge, tool, pole ect becomes a large contact surface area. Both feet on the ground with wet shoes. In fact with a power tool its possible to have both hands on it at the time of a fault.

IEC 60479 gives 850 ohms at 125 volts with salt water.

Water wet would be places where wet hands are common or likely to be found: pools, spas, bathrooms, greenhouses, sinks, outdoors.

Children are a difficult challenge as ethical issues are raised as to whether or not they can consent in scientific experiments. However, considering smaller hands and thus contact area the difference may not be so big. At least resistance wise. Whether or not children have a lower ventricular fibrillation threshold would be impossible to test for, for obvious reasons.

ProMbrooke:

A handle on a fridge, tool, pole ect becomes a large contact surface area. Both feet on the ground with wet shoes. In fact with a power tool its possible to have both hands on it at the time of a fault.

IEC 60479 gives 850 ohms at 125 volts with salt water.

Water wet would be places where wet hands are common or likely to be found: pools, spas, bathrooms, greenhouses, sinks, outdoors.

Children are a difficult challenge as ethical issues are raised as to whether or not they can consent in scientific experiments. However, considering smaller hands and thus contact area the difference may not be so big. At least resistance wise. Whether or not children have a lower ventricular fibrillation threshold would be impossible to test for, for obvious reasons.

ProMbrooke:

However, when all is said and done, I think table 41.1 needs to be re-visited again.

But is that based on the fact that RCDs can't be trusted?

Table 41.1 is dry condition only.

Other than reliance on RCDs to achieve 40 ms disconnection time for additional protection, is IEC 60364 deficient in any other respect?

If all disconnection times are reduced to 0.2 s, what do you propose we do about circuits > 63 A (sub-mains etc.) that currently have disconnection times of 2 s and 5 s (and do NOT align in any way, shape or form to IEC 60479)? How will we achieve disconnection times and selectivity for these circuits?

If Table 41.1 is revisited for these reasons, other parts must be also ... would be good to hear your recommendations and reasoning on these other circuits?

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site