Thus, I am advocating for a touch voltage limit of 25 volts be established for wet locations with a disconnection time of at most 0.2 seconds for 230 volt supplies.

gkenyon:

So, what I'm trying to do is engage to see whether there is an issue here, or whether it's one of "preference engineering" ?

Well, if anything with the advent of AFDDs we have proof of preference codes.

But, that aside, it seems like delayed clearing can be harmful going by the IEC's own established values.

I understand RCD are supposed to take care of this gap, however, I stained by the fact RCDs can and do fail and should not be the sole means of ADS.

Zoomup:ProMbrooke:Zoomup:ProMbrooke:gkenyon:

When PME was introduced, we were still in the "post-war" period.

Now we are in a position where, in existing urban areas, PME is here to stay.

I understand some DNOs are offering TN-S for new-build - of course, there is a slight cost increase for the extra core.

With TN-S, you only need one failure after broken PE, on circuits where RCDs are not used. Where RCDs are used, I thought you said you weren't happy with reliance on the RCD?

Your point regarding earthing is very valid ... for all system types. The impact on the effectiveness of main bonding due to the change to plastic service pipes can't be underestimated. I have measured the effective combined earth electrode resistance of my water supply pipe, which is still lead from the street, and it's well under 4 ohms.

How should we deal with that? Germany insist on foundation earth electrodes, which achieve a similar result ... but that idea keeps being shot down here in the UK. I'd like to see some alternative approaches considered. Don't forget, the loss of plastic service piping is not a fault of the DNO, it's a result of health & safety (replacement of corroding metal gas mains for plastic) and public health (replacement of iron and lead water pipes for plastic) and far outside the DNO's control.

Two failures for TN-S without RCD, Three failures with RCD. RCDs aren't 100% reliable, hence why I advocate a foundation of low loop impedance and rapid disconnection.So what happens when I am outside in the garden and I get a shock on an old non R.C.D. supplied socket, due to a fault with an appliance or appliance flex, if I am in contact with 240 Volts mains. Let's say 5 Amps is flowing through my body. Will the 13 Amp plug fuse blow and save my life?

Z.

.

Thats where CPCs come in, in that they would cause the fuse or MCB to open in 0.2 seconds or less.Not if the cable is just two core they wouldn't. Or if the appliance is all insulated=Class 2.

Z.

Right, where you would have a double insulated tool, which is not capable of becoming live ie made of plastic.

Right, where you would have a double insulated tool, which is not capable of becoming live ie made of plastic.

gkenyon:ProMbrooke:

Thats where CPCs come in, in that they would cause the fuse or MCB to open in 0.2 seconds or less.Doesn't that happen anyway ... in TN systems where the loop impedance ensures operation in 0.1 s?

The issue being, that, in TN-S systems (no RCD), you're limited in circuit length with Type C mcb's.

Also, interested where 25 V comes into the equation here? To do that, you've got to oversize the cpc, not undersize it ... and even then, may not be possible in TN-S due to the effect of the distributor's cpc ?

It does, but going by table 41.1 we are allowed a loop Z high enough to cause 0.4 seconds disconnection.

Type A, B, or C MCBs, fuses, or the like you are always limited in circuit length be it voltage drop or should the RCD become inoperative.

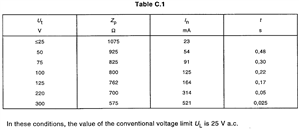

25 volts is the highest touch voltage under infinite time allowed by the IEC in wet locations according to Table C.1 in IEC 61200-413. Where higher touch voltage are found, disconnection is required. At 125 volts 0.17 seconds is required. With a reduced size CPC, even faster times are required.

AJJewsbury:Thus, I am advocating for a touch voltage limit of 25 volts be established for wet locations with a disconnection time of at most 0.2 seconds for 230 volt supplies.

Curiously, we seemed to have exactly that for some special locastions back in the 16th Ed (1991) - specificslly construction sites (section 604) and Agricultural and Horticultural Premises (section 605) - so somewhere along the line it seems that someone decided that 0.4s plus additional protection (e.g. 30mA RCDs) was an improvement.

Perhaps oddly the same requirements didn't appear for bathrooms or pools at the time, even though there was no requirement for RCDs (although 230V was banned from the wettest part of those locations and supplementary bonding was required).

It's perhaps a mute point anyway, since most final circuits are protected by B-type or C-type MCBs (or similar in RCBOs) - so disconnection will be within 0.1s anyway (and 0.04 if a 30mA RCD is functioning) - so a change to 0.,2s in the regulations perhaps wouldn't result in any significant safety improvement in practice.

- Andy.

I agree in full in that MCBs will always trip in a few cycles when sized to a 0.4s Zs. However, if fuses are employed a gap could be present, hence why I think the regs should cover all possible scenarios.

AJJewsbury:Right, where you would have a double insulated tool, which is not capable of becoming live ie made of plastic.

Which is fine for indirect contact/fault protection, but 30mA RCDs also provide protection under direct contact situations - e.g. damage to the appliance's flex exposing the conductors.

It's also hard to control loop impedances where long thin extension leads are in use - it doesn't take a huge amount of 0.75mm² orange flex running down the garden to get to the point where neither the MCB nor the plug fuse will reliably provide 0.4s (let alone 0.2s) disconnection.

- Andy.

If both parts of the double insulated flex are damaged, and no concentric screen exists around the cores, direct contact is very much possible and thus RCD is needed.

I like to think this also fits the 3 strikes rule: Both the inner cores, outer covering and RCD must fail for a lethal hazard to exist.

You are correct, long flex leads are reasonably likely, and can certainly increase R1+R2, hence why I believe double insulation on tools are best in wet locations.

This is also the same logic I have for possibly mandating that sockets be present every 2 meters in homes and some wall spaces in commercial occupancy- going by a 70*C R1+R2 assures that 2 meters of appliance or tool cord adds negligable R1+R2 on the final circuit.

Forgive my spelling btw, I can't see to get auto correct to work on this forum. That would be my fault.

ProMbrooke:Zoomup:Not if the cable is just two core they wouldn't. Or if the appliance is all insulated=Class 2.

Z.Right, where you would have a double insulated tool, which is not capable of becoming live ie made of plastic.

I think the issue Z is highlighting is that Class II products (and perhaps tools - but "live working" tools are not a measure for protection against shock etc. alone) is that they can get broken when being used. Under those circumstances, a single fault outside the provisions of the product standard (broken appliance casing, or damaged flexible cable, for example) exposes ordinary persons directly to live conductors ??

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site