We have been asked by operations to look at streamlining isolation tasks for mechanical and process jobs.

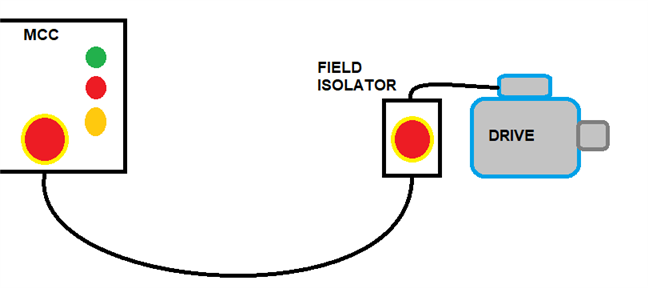

I have suggested having local isolators next to the required drives (belt driven fans / pumps etc), which can be operated by anyone, instead of MCC located isolators or even fuse pulling, done by specifically trained people.

I cannot find anything about best practice or pro/cons on something like this, so I a hoping people here could offer advice?