Gents,

Bit of a headscratcher here that I could do with a bit of help with:

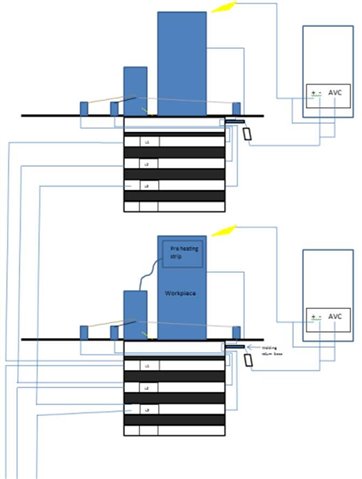

There is a rotating turntable used for the purpose of being connected to an automatic welding machine.

Situated on the turntable is typically a welding workpiece & three single phase sockets that are then used to deliver power to a three phase preheating unit preheating unit.

The power to the sockets is delivered through slip-rings, as is the welding return current for the welding machine.

This supply to the slip rings also carries on providing power to another turntable.

This turntable is earthed as required for fault protection on the pre-heating circuit; as if a fault arose then protection device would be required to operate.

The trouble comes around when the welding machines AVM (Arc voltage monitor which decides the height of the arc welding needle from the workpiece) are used. As they are both connected to the workpiece and the workpieces are both connected to each other through common earthing it is believed that the systems may cause malfunctions with each other when both workpieces are being used.

I have made a rough sketch below, the small writing that you probably can't see either says: "Workpiece", "Welding return boss" or Pre heating strip"