Hi

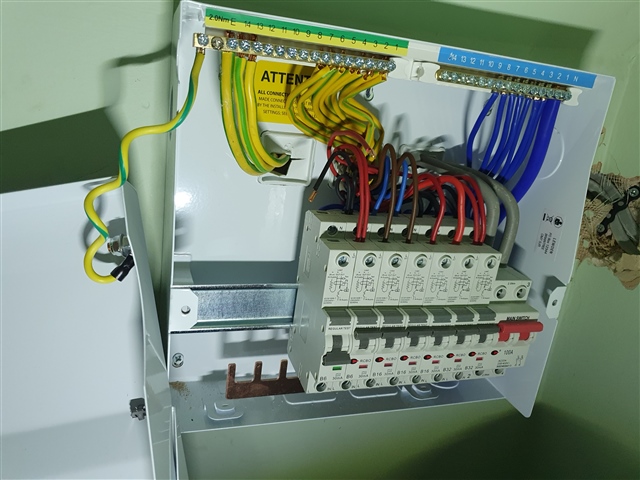

I am coming across more curve consumer units with Lewden RCBO's in and they are causing me a dilemma.

As you will see in the picture the line conductors pass straight in front of the neutral terminal screw, the only way to check torque on the neutral is to remove the line conductors or risk damaging them.

So far providing the line terminals are tight I have not checked the neutrals as I believe i would be doing more harm than good with work hardening and flattening of conductors, and noting this on my report.

What would you do in this sittuation?