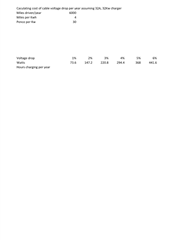

I do quite a few EV charger installs, more and more seem to end involving long SWA cable runs to garages etc with voltage drop driving cable size.

In many cases I am running an EV charger, other bits in the garage and garage lighting circuits from the same cable run.

According to my understanding of the regulations lighting circuits are only allowed to have a 3% voltage drop between the incoming supply and the accessory compared to 5% for power. Therefore voltage drop for the garage lighting ends up being the driver for cable size on the garage supply cable.

I get the impression that others bend the rules and have certainly found some installs that do not comply even with the 5% guidance, I appreciate that most of the time we can get away with it but I don't want to end up with upset customers and maybe having to replace an expensive cable.

But by calculating this way, am I being unnecessarily stringent with my calculations. I realise that this assumes worst case supply voltage from the grid which I feel I have to stick with, but for example are typical modern LED light fittings more tolerant to low voltage supply compared to filament lamps and therefore the guidance in 7671 is actually out of date?