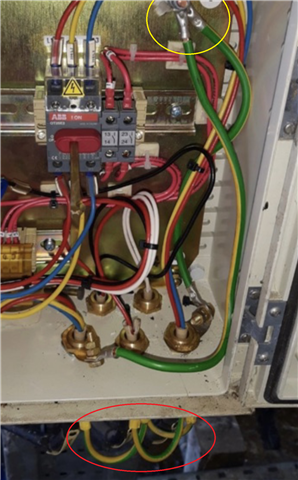

I see it a lot where the SWA isn’t serving as a protective conductor which I know it must still be earthed at one end due to being an exposed conductive part. My question is if multiple SWAs are all earthed at the supply end and meet again at a bit of equipment if we then connect all the SWAs together locally is this still classed as earthing even though they are already earthed at the supply?