Hi All,

Ive inherited a job, where we have a large LV Switchpanel sitting ontop of an open concrete trough.

I have approximately 18No. 95mm/120mmm SWA 4 Core cables feeding panel boards exiting into the trough below from the switchpanel for about 3 meters before it exits the trough and below the building but still above ground level (the buildings on stilts) onto a tray.

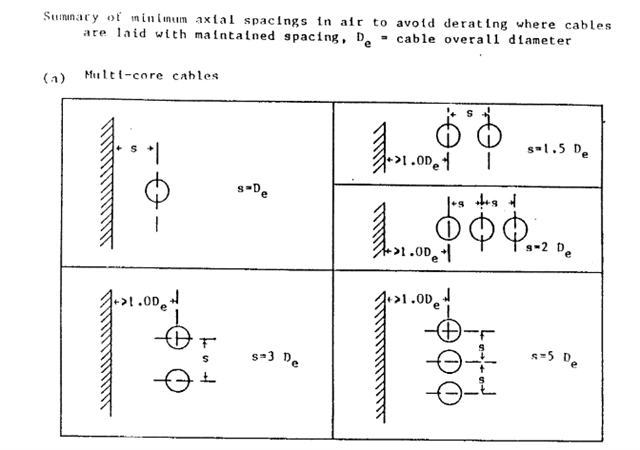

I am just struggling to find the correct de-rating factor in BS7671, 117-120 doesn't seem to quite fit the bill, but 119 seems to be the closest. But cant see it working, especially as it recommends 75mm apart, witch is 18 x 75mm = 1350mm and a maximum of 6 cables

This must be a reasonably standard arrangement, but i am stumped.

Any help would be much appreciated.

Thanks