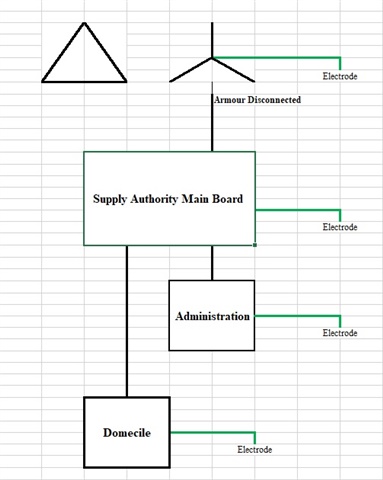

I have found two earth electrodes at each , this is due to supply authority providing earth elecrode at their main panel and contractor supplying earth electrodes local to two seperate installations. I have two questions:

Is there an issue with using more than one earth electrode for each installation i.e. both the supply authority electrode connected to the installation via feeder cable SWA + supplimentary earth cable, and a local earth electrode connected to the main earth bar of each installation?

The project consistes of two buildings, one is a administration building and the other is a residential building with multiple demociles, both are approx 500m from the supply authority earth electrode.

I note the measured Earth Fault Loop Impedance values are low enough to comply with BS7671.411.4.202, Table 41.3 and as such they comply with Note 1 of BS7671.411.5.2. while I understand the use of Overcurrent Protection Devices without RCD protection for final circuits are considered acceptable, are there any issues I should take into account.

Note I am in the middle east and the ground is as dry as it gets there has been no rainfall or water on the ground since early April therefore the contribution of the general mass of earth to the fault path measured values are as high as they will ever be.