HI All

My turn to need some help........

I have a three phase, 11.5KW motor complete with contactors etc in the MCC. (It was 8.5KW three phase motor and its been upgraded to an 11.5KW three phase motor with some upgrade of wiring, contactors etc - all works carried out by myself - so I cant blame anyone else - from design calcuations and cable sizes to specification of the contactors etc - installed by myself too, so I cant blame anyone else for this either.

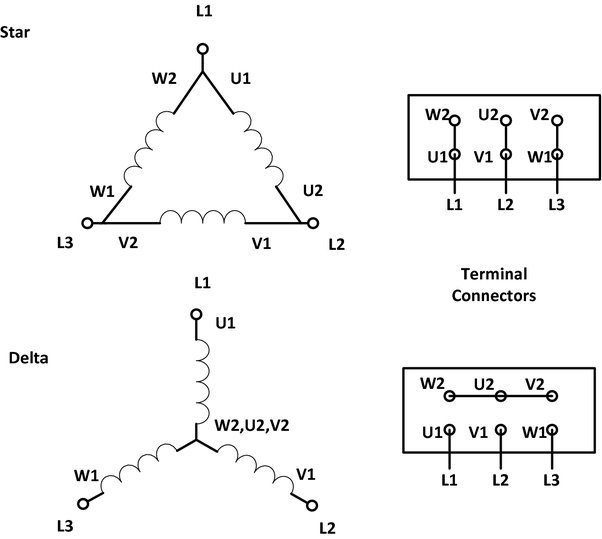

This motor has Three contactors, as is usual with star/delta, and, as usual, with two contactors working together (! &3 in this case with the shorting out bit on top of contactor 3) and one contactor working alone. (Contactor 2).

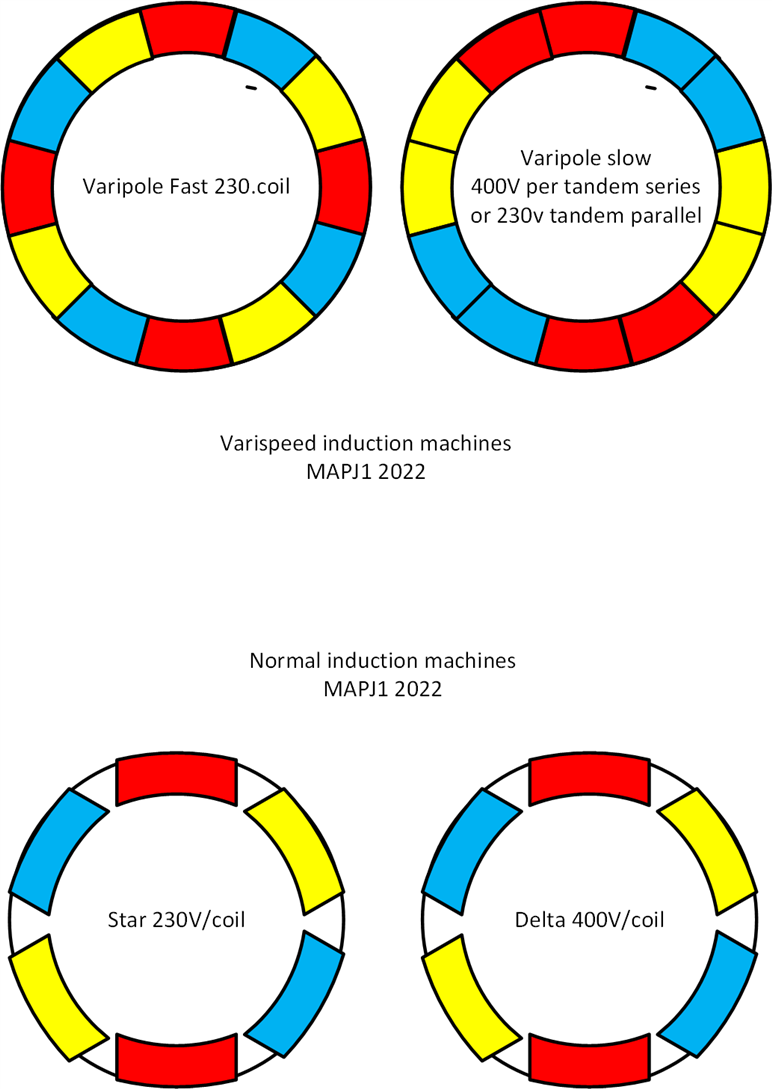

This is wired - I'm very sure - in a typical star/delta set up but with no time clock. It is - I know - different to star/delta and is a high speed/low speed motor control.

Both Contactor 1 and contactor 2 have overload protection as this motor can be run in Low Speed or in High speed and left in that mode for indefinite periods of time.

I'm virtually certain that the links in the motor should be removed all together and I have done so.

The controls are not apparently trend for the contactor control circuit, but Trend does the flow switches, dampers, filters etc and in auto must play a part in start stop functions and high speed/low speed functions.

I'm fairly certain that the door switch high and low speed do not use the trend controls - its in hand effectively. (Four options on the Door switch selector - High speed, Low speed, Off, auto).

Any way

- This motor functions in High speed (Contactors 1 and 3 in a typical star/delta set up) probably proving that I have connected up the motor winding correctly. I'm certain I have.

Motor Direction is obviously correct too.

- This motor does not do anything in Low speed function - even though contactor 2 engages - when the low speed door switch function is selected - and voltage passes through contactor 2, to the motor (the motor receives power from the MCC, through the windings and - inevitably back to the MCC at the bottom of contactor 1.) The motor does zero. I feel the circuit is incomplete.

Now - if I were to only wire this motor in (Delta?) winding - slow speed - I'd install the links into the motor -3 of - I feel these links are missing - in the MCC

In high speed - (star?) winding - the motor links are provided by contactor 3 which is linked out at the top of contactor 3 - when contactor 1 pulls in - contactor 3 pulls in and a circuit is formed.

I hope I have my star delta descriptions correct? I get them mixed up.

I'm missing something very fundamental and elementary here - I know I am - please do inbox me if you think you can help as I feel this forum might prove difficult to diagnose a something stupid on my part.

I'm near Woking, Surrey and the job is in Epping Forest, London and is a swimming pools main AHU air handling Supply motor.

I very seldom, these days, get to do star/delta motors and clearly, don't understand high speed/low speed motors.

Kind Regards

Tatty