Hi all,

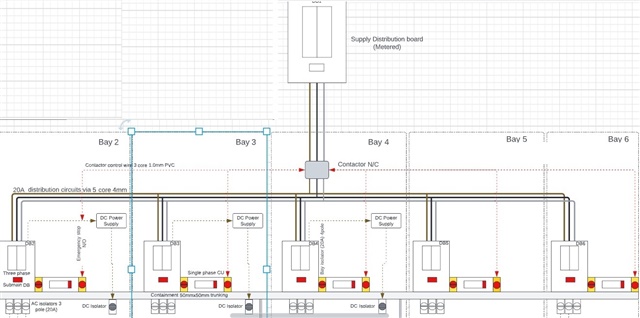

With more of a renewables background ive not done much in the way of safety circuits, but im trying to design a small lab set up as follows for solar PV training

main incoming supply split to 5 separate bays each with their own TP DB for various circuits, each having their own E stop

Id like to have a contactor that would either isolate all bays when ever an E stop is pressed or simply isolates the bay concerned.

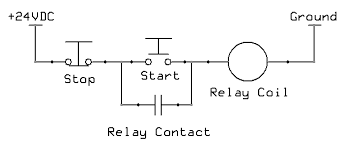

From a simple perspective i thought a N/O E-stop with a NC contactor. but most E stops seem to be N/C (and have read better suited in safety systems?) but this would mean the contactor would require to be N/O. which is fine.... i assume, but that it will likely (fingers crossed) never be utilised so that it will be being held in unless their is a safety issue. Is it Ok to have a N/O contactor constantly engaged or is that bad design?

Id like the contactor/s to be needed to be reset perhaps by key or some other manual means any advice here?

thinking again im not sure how a single contactor could work as the load would need to be split into the 5 bays which would mean further OCPD's downstream of it,

so perhaps 5 separate contactors all linked from the Estops to A1 (or not linked if we are only isolating each bay individually)

anyway thanks in advance!! Image below shows just a single contactor