Hello,

My company is building machines that consist of many machine parts such as screw conveyors, tanks, grinders, pipes and other machinery.

I´m following IEC 60204-1 in my design and I´m unsure of where I´m required to add equipotential bonding to my drawings and I do not want to overdo it if it is not required.

The standard states that the flollowing shall be connected to the protective bonding circuit:

- Conductive structural parts of the machine

(Our machine parts (Screw conveyors, tanks, Pipes) are mostly made of stainless steel so those must all be connected to the protective bonding circuit, right ?)

- metal ducts of flexible or rigid construction

- metallic cable sheaths or armouring

- metallic pipes containing flammable materials (We do not have any flammable materials in our process)

- Flexible or pliable metal conduits

- constructuional parts subject to mechanical stress in normal service

- flexible metal parts, support wires, cable trays and cable ladders (We just bond the ladders, trays with a bare copper conductor along the entire length)

So my question is mainly about how much bonding we should do on the machine parts.

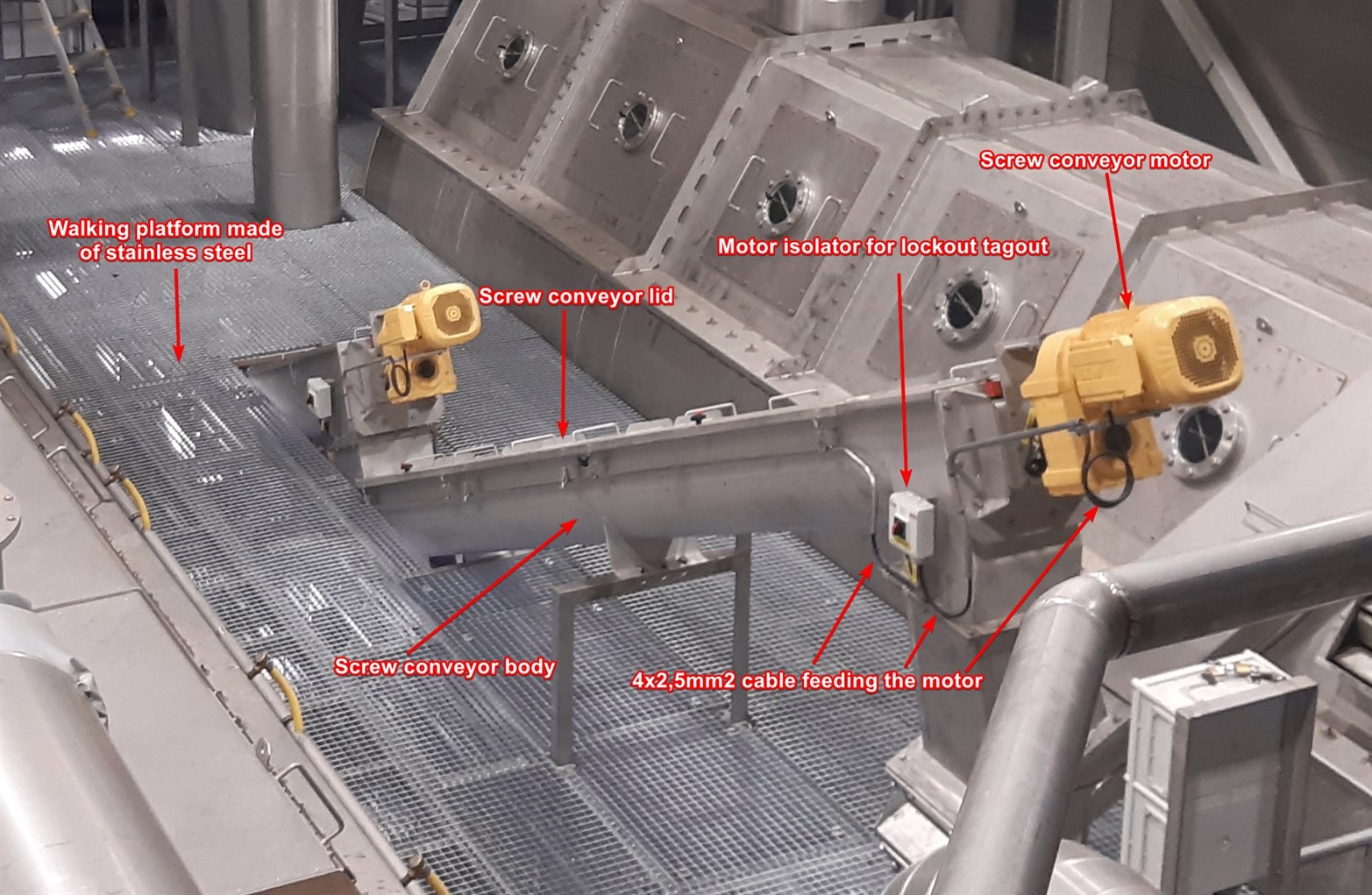

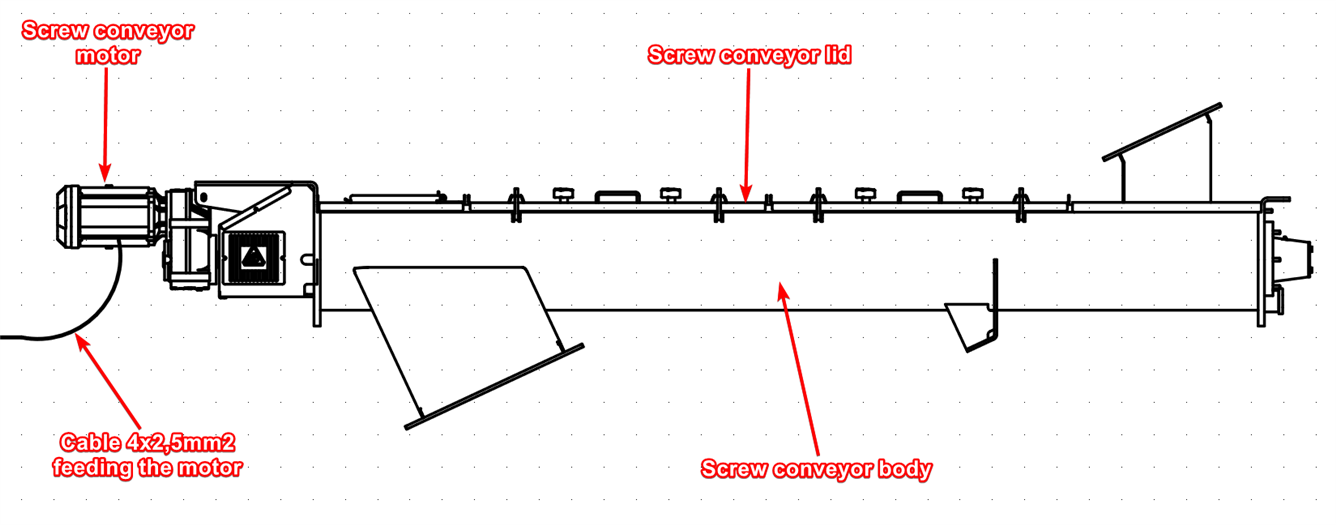

If we take a screw conveyor for example, it consists of the flollowing

- A screw conveyor body (made of stainless steel)

- A lid on the screw conveyor (made of stainless steel)

-A 3ph 400Vac motor attached to the screw conveyor body

The cable 4x2,5mm leading to the motor has 4 conductors (BN for L1, BK for L2, GY for L3 and GNYE for PE)

So obviously the motor is connected to the protective bonding circuit through the PE conductor in the cable connected to the PE terminal in the motor connection box

Note that there are no other electric parts other than the motor on this screw conveyor.

Should we additionally connect the outside of the motor casing to the protective bonding circuit ?

should we additionally connect the screw conveyor body to the protective bonding circuit ?

should we additionally connect the screw conveyor body to the protective bonding circuit ?

Since the motor is the only electrical consumer on the screw conveyor it is highly unlikely

or even impossible for the screw conveyor to become a live part since the cable does not run along side the screw conveyor, with that in mind can we do without connecting the screw conveyor body and lid to the protective bonding circuit ?

Should we connect the motor body to the protective bonding circuit ? (Even though the motor is already connected to the protective bonding ciruit through the GNYE conductor in the cable feeding the motor)

Many thanks,

Steinar R