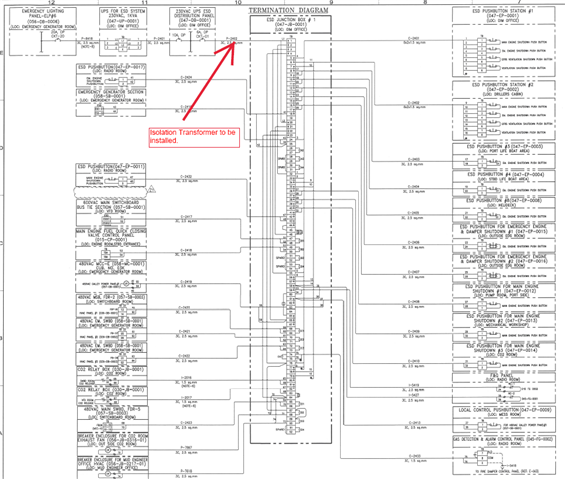

We have a emergency shutdown system on our rig that is wired in such a way the relays always have a minimum of 90v on L2 side of the coil so it is intermittently not opening on ESD activation. I believe this is incorrectly designed as we have a three wire three phase system, no neutral so in theory 110v each phase and 230v across any two phases.

Intermittently when activating the ESD buttons the activation relays will not open because of the constant voltage of anywhere between 90-110v on L2. I am trying to convince my engineering department that this is incorrect and we need to redesign but it is difficult as they don't understand the issue.

What i would like to propose to temporarily fix the issue is to put in a Isolation transformer and tie down the L2 side to earth of the secondary to give us a 0vL2 and 230v L1. This guarantees the relays will work when intended but i am not 100% sure this is allowed?

Can someone please assist me if at all possible.

AJ,

AJ,