Was browsing though YouTube when I saw (but don't advocate) this vid entitled 'Awesome Idea! How to twist electric wire together!': https://www.youtube.com/watch?v=qHoyF4yKhjU

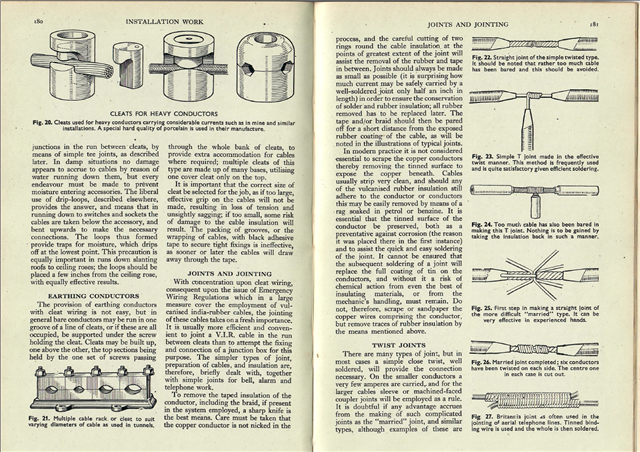

Well, reminded me of how I was taught to solder joints on power cables, and also part of a book I have in my collection, entitled General Electrical Engineering edited by Philip Kemp MSc(Tech) MIEE AIMechE (which is undated, but I believe is from the late 1940s or early 1950s).

I hope I'm permitted to post the extract of the two pages I had in mind, as it's a very old publication:

Certainly of interest, and shows there's a lot we used to know ... and how much depended on the skill of those who installed electrical equipment in days gone by.