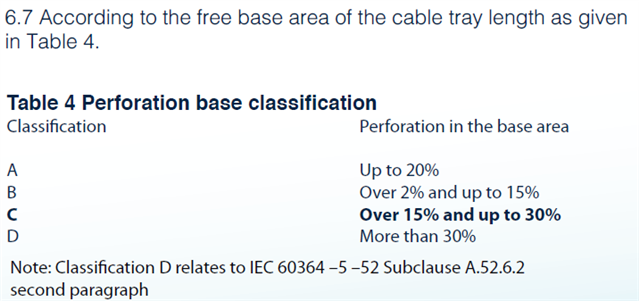

Is anyone aware of a cable tray manufacturer that makes perforated cable trays with more 30% or more of holes? I've checked a few online and they all seem to be classification C. Can this only be achieved by using basket?

Extract from BS7671:

APPENDIX 4 (Informative)

CURRENT-CARRYING CAPACITY AND VOLTAGE DROP FOR CABLES

7.2 Other Methods

"Cable tray systems: A perforated cable tray has a regular pattern of holes that occupy at least 30 % of the area of the base of the tray. The current-carrying capacity for cables attached to perforated cable trays should be taken as Reference Method E or F. The current-carrying capacity for cables attached to unperforated cable trays (no holes or holes that occupy less than 30 % of the area of the base of the tray) is to be taken as Reference Method C."

Extract from manufacturers data sheet: