Hi everyone, im after some help!

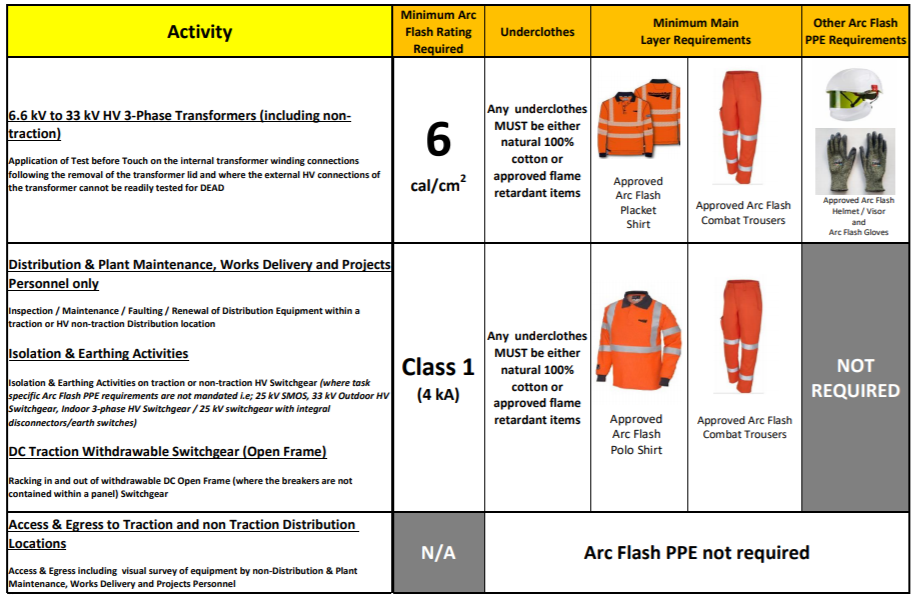

I work for an American company who have a lot of requirements and procedures for determining Arc flash but are all US and OSHA regs and rules. My team work on CNC equipment so our work is mainly live testing on 3 phase and low voltage circuits in panels. I'm trying to determines the UK requirements for Arc flash. I'm needing to know info like Arc flash boundary, how to determine PPE, calculations etc.

Any help would be great !

and for higher power stuff

and for higher power stuff