Looking at installing this compressor, wonder how to interpret the instructions, do I need a DOL.

https://dccf75d8gej24.cloudfront.net/documents/(000112350)_XE29-270%20Air%20Compressor_ISS%205.pdf

specifications etc

https://www.machinemart.co.uk/p/clarke-xe29270---industrial-air-compressor-230/

All the instructions say about electrical installation is

The power cable from the main supply must be large enough to carry the starting and running load of the electric motor. This is particularly relevant if the compressor is some distance from the source of supply. 6. Electrical installations should be completed by a qualified electrician. 7. Electrical connection to the mains supply must be via a suitably fused (see table on page 6) approved plug or isolator (allowing sufficient capacity for motor starting). If using a circuit breaker, ensure it is motor rated and of sufficient size to allow for motor starting.

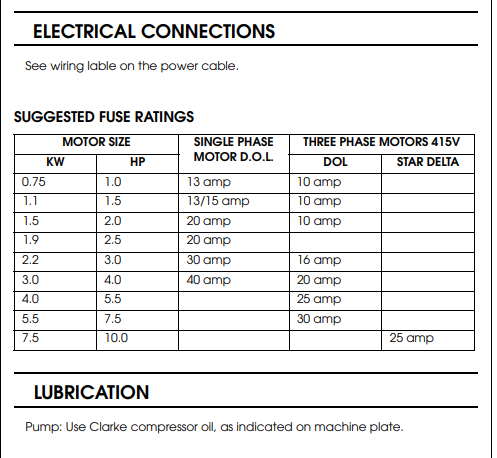

Then later it has the table below for DOL ratings.

But the instructions don't say there needs to be a DOL starter, so can I take that it's not required but if you want one these are the specifications.

The compressor is running a sand blasting cabinet in a domestic garage, the only moving parts are really the motors on the compressor that have good guards on.

The only real risk I can see is if someone decided to work on the compressor with the guards off. if someone was caught in the motor the only places reachable would be on the floor or mounted on the compressor, i don't fancy doing either.

The current plan is to have a 32a socket with built rotary isolator but no DOL. The compressor has two 3hp motors and sequential starting so that they can run on a 30A supply, as per other post I am using a 32A type C RCBO having eventually found one.