I have a situation in a Theatre environment where the requirement for application of grouping factors has been picked up rather late in the process and the consequent cable size increases (which are significant if the figures from the table in BS7671 are applied) mean the containment is too small and we can't get the cables in the breaker terminals or the connector terminals.

Scenario is a series of panels with 400A supplies, with protective devices of various sizes and a number of outlets ranging from 32A single phase up to 3-phase Powerlock (for 250A supplies). The original design was that this was all in one panel, so the panel building standards applied, to the internals, rather than BS7671. Then somebody decided to split the outlets away from the panel by varying distances (from around 2m to 20m) and connect them with trunking. Now BS7671 needs to be applied to the installation of the link cables. Sadly at the time they just used the internal panel cable sizes to size the containment routes and didn't allow for grouping. The panels are used for connection of temporary equipment that a touring show or a given production may need, so not very predictable really.

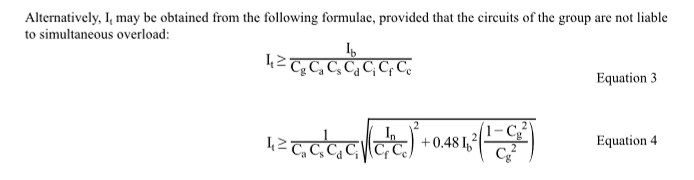

There are typically 6 or 7 circuits running in each trunking link. They are generally of different ratings/capacities and are overall limited by the 400A supply to the breaker panel. This does however mean that they could all be loaded to more than 30% (the figure below which they could be ignored for grouping - generally this works out at 50-70% depending on the panel) so without imposing an operational limitation below the panel maximum which the client may not be very happy about, I'm struggling to see a way round using the tabulated grouping factors. These take the 95mm2 cable for the Powerlocks up to 400mm2 (based on a 70 degree operating temp). We're generally looking at 2 sizes up from the nominal for most cables with this method.

The grouping factors say they are for identical cables equally loaded. We have different sized circuits and they may be loaded evenly or unevenly.

Whilst we can come up with a number of scenarios of circuits loaded at different levels, and it is is unlikely that they would all be used at once and proportionately evenly loaded, it is entirely possible that all circuits from a given panel may be used at once to more than 30% each. On this basis what options do we have but to use the tabulated grouping factors (which seem to be generally regarded as being pretty conservative)?

There are a lot of practical limitations on site, as were considering options around changing to run some (or all) of the circuits in SWA and keep them spaced apart but we likely can't do this everywhere.

Anyone have any good engineering suggestions for an alternative approach to the grouping factors/cable calculations? This all starts to get particularly ridiculous where the breaker panel and outlet box are either side of a wall and we may need to put additional termination boxes on both sides so we can upsize about a metre of cable run!

Jason