Question on the correct point to bond extraneous-conductive parts to and what CSA to use for TN-C and TN-S systems

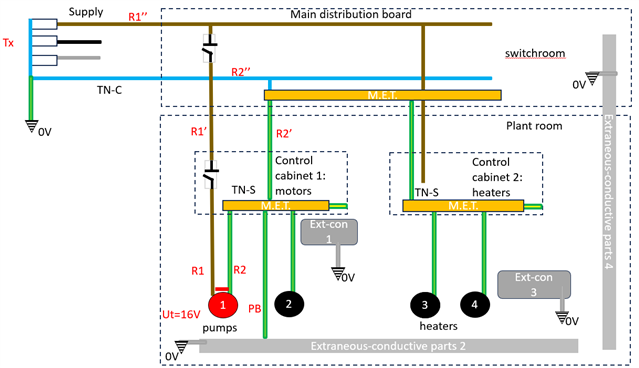

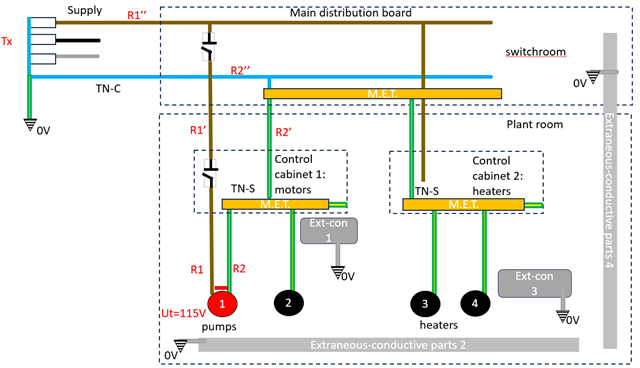

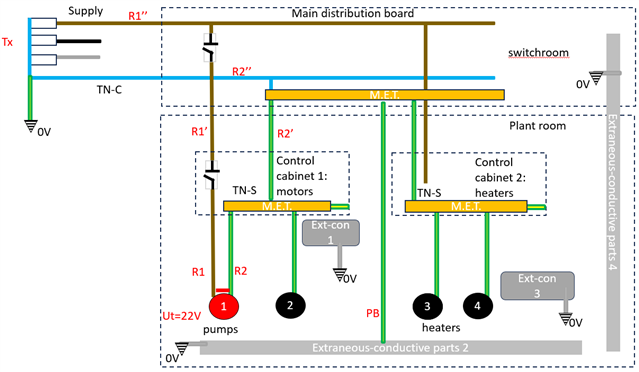

We have two control panels in a plant room supplying a number of different loads (pumps and heaters). Both of the control cabinets have separate supplies and CPC’s (TN-S system) and are supplied from a main distribution switchboard located in a separate room – the main distribution board is on a TN-C system.

Supplementary bonding isn’t necessarily required for this installation but obviously we want to bond any extraneous-conductive parts so as to keep touch voltages between accessible metalwork below 50V in the event of an earth fault

The control cabinet line conductors are 185sqmm (although the actual CPC’s according to adiabatic and keeping Zs to appropriate values need only be 25sqmm, nevertheless the total Cu equivalent c.s.a. for the Steel armour is about 80sqmm)

Option 1 : Would you bond the extraneous parts back to the control cabinet MET’s and the control cabinets to each other (they are located next to each other so can be touched at the same time) – BS7671: the protective bonding not less than half required CPC ... so 16sqmm or the maximum being 25sqmm size for TN-S system.

Option 2: Would you bond extraneous conductive parts back to the main distribution board MET with 50sqmm [max size required forTN-C system) as the main dist. Board line conductors are over 150sqmm (I’m not sure if you can apply the adiabatic in this instance??)

Option 3: would you bond extraneous-conductive parts back to the control cabinets with 16 or 25sqmm AND back to the main distribution TN-C system with 50sqmm ?

For me, if it is option 1 then this would result in a lower touch voltage that option 2. but i'm not sure which option is the correct one according to the regs. And if option 1 then the 50sqmm rule for TN-C systems need not apply and my protective bonding need only be max 25sqmm ?

bonding to the main distribution MET Ut=22V (fine)

bonding to final control cabinet METs Ut =16V