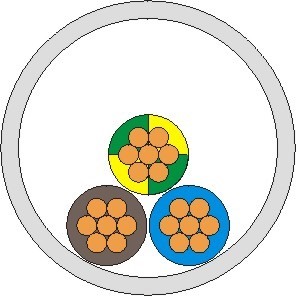

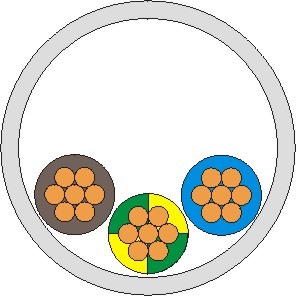

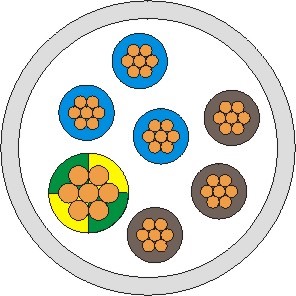

I am knackered - I have spent several hours today pulling in 3 x 16 mm² into 25 mm conduit. OSG promised me that it was possible and indeed it has been, but how difficult does it have to be?

Lube the cable, up the ladder, pull a bit, back to the beginning, lube the cable, back outside again, up the ladder, pull a bit. Down the ladder, move the ladder, up the ladder, pull a bit, down the ladder. Repeat. Repeat. Repeat.

Am I missing something?