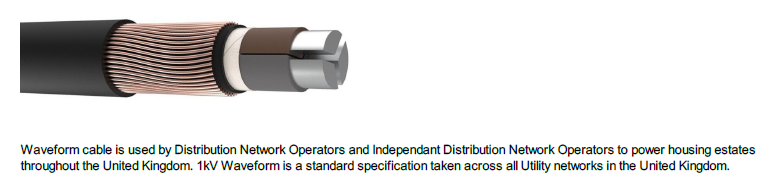

Two relatively long 300mm2 3-core Waveform cables in ducts below ground supplying an industrial building. Currently the cables belong to the DNO but the contractor has permission to adopt them into a new proposed 1MVA PV/battery arrangement if he so wishes. The conductors are configured as three lines in parallel, outer copper wire screen in one cable as neutral and earth in the other.

Its not a good start with the reduced neutral and plenty of machine control in the plant but no issues apparent. Parameters for normal design procedure are not yet clarified as everything is at an early stage but I was just wondering about the BS7671 perspective. I have never used the cable as it is generally for DNO application. The cable cannot be touched at any point other than at both ends.