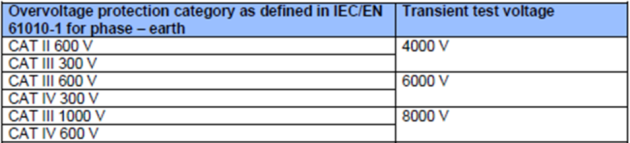

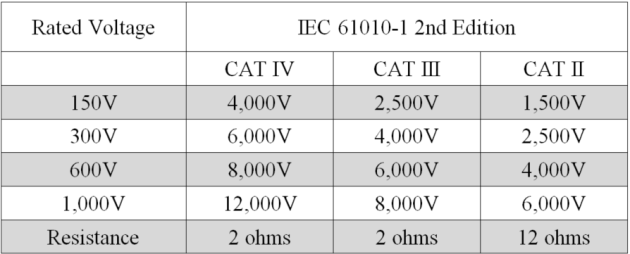

I have recently been reviewing the technical details for a popular brand of lever type splicing connector and, according to the information on the manufacturer’s website, the connectors are only rated for use in overvoltage category II applications. My understanding is that for a fixed wiring installation to comply with BS 7671, all equipment must be rated for overvoltage category III (regulation 443.6.2 and table 443.2) i.e. be capable of withstanding an impulse voltage of 4 kV. The certification data, also published on the manufacturer’s website, states that the connectors have only been tested to 2.5 kV.

I have queried this with the manufacturer, who advised that the 4 kV electrical strength test only applies to IT equipment.

I may well have misinterpreted the requirements, but I would be interested to hear anyone else’s views on this.