As above,I am hoping to run a 1.1kw machine using 120uf start and 60uf run capacitors as suggested

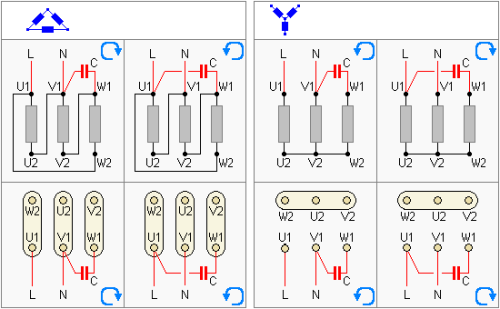

by a motor text book.To work,the motor windings will be changed to delta for the reduced voltage.

I understand the output power will be reduced by a third.Wondered if anyone has successfully used

this method?Thanks for any replies.

Regards,

Hz