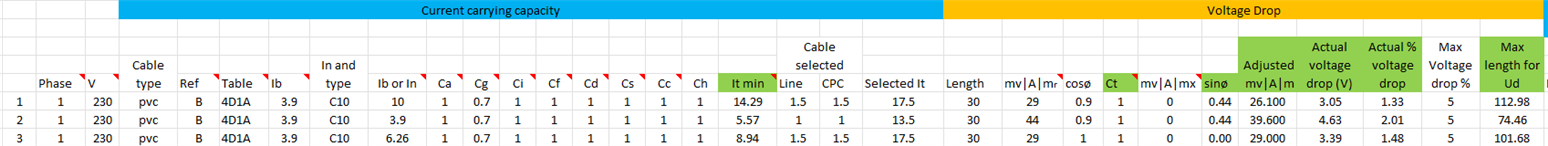

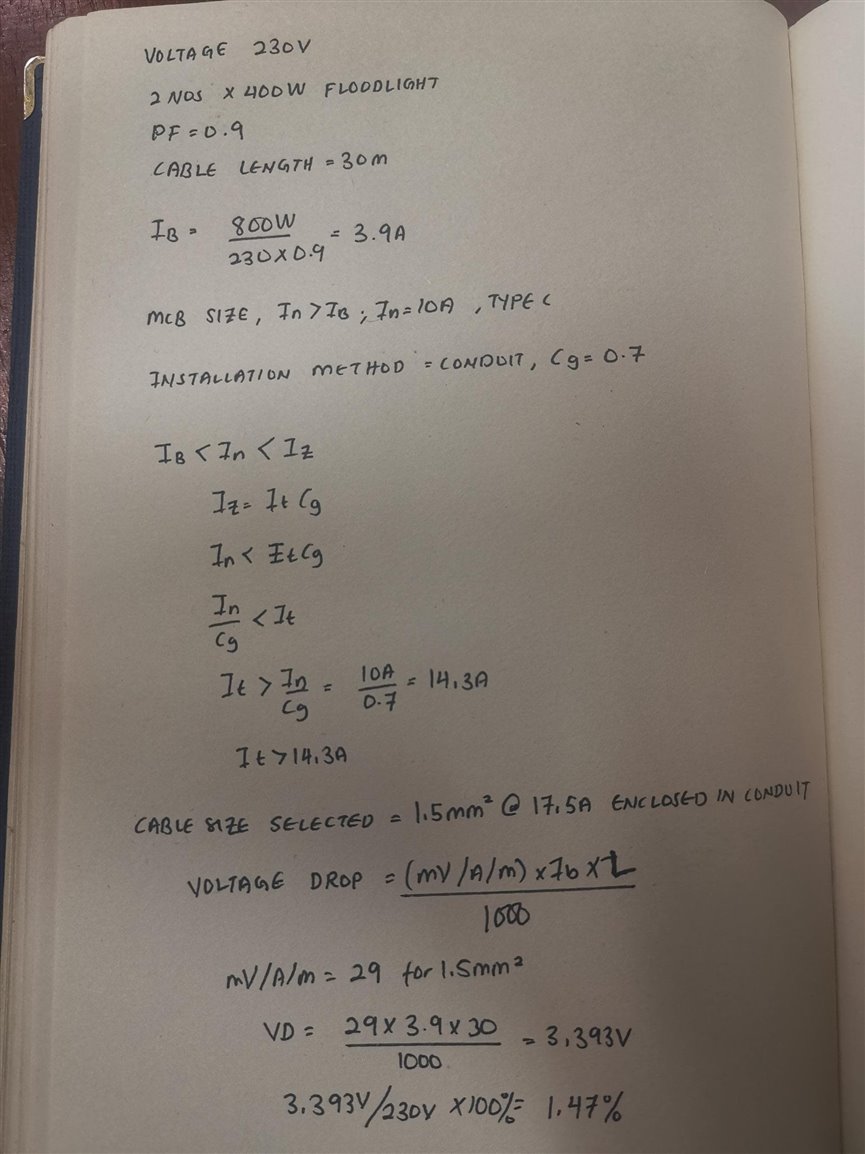

I'm trying to design one single line diagram (just for learning session) and one of my circuit is having 2 nos. x 400W Floodlight with 1.5sqmm Cu/PVC cable, with 30m cable length, MCB rating 10A all the calculation such as load current Ib, MCB rating In, derating factor, cable carrying capacity and voltage drop is shown in the above photo.

Based on my calculation, my Ib < In < Iz is 3.9A < 10A < 17.5A respectively, with voltage drop of 3.933V @ 1.147% from 230V,

However, after discussing this with several knowledgeable individuals and referring to previous single-line diagrams that I've encountered, they've indicated that 1.5sqmm might not be sufficient, instead they requested me to change it to 2.5sqmm. (I do understand 2.5sqmm is better than 1.5sqmm in terms of cable-current carrying capacity, and voltage drop).

My query is, where might my calculation have gone wrong in this context?