I’m sure that there used to downloadable PDFs of older editions of BS7671 on the IET website. Can anyone direct me to them please. I want to check the original 17th.

Thanks in advance.

I’m sure that there used to downloadable PDFs of older editions of BS7671 on the IET website. Can anyone direct me to them please. I want to check the original 17th.

Thanks in advance.

I'm not sure I ever remember seeing them. You might be able to view them in the IET Library.

Some of us do have extensive technical libraries ourselves ... can we be of assistance in helping look something up for you (or indeed, we may know the answer off-pat, you never know) ?

Where abouts is this library?

The IET library is at Savoy Place in London (some titles, though, they can post out to Members).

My library is associated with my home office!

I’m just wondering when regulation 521.5.1 came in. I wanted to look it up in the 17th and 16th….

Which para are you looking at specifically? Eddy currents (paras 1 and 2), or the "parallel cpc" (para 3)?

We'll have to look back further than 16th Edition when talking about eddy currents. The first 2 paragraphs are effectively very old and can be traced back to the 15th Edition pretty much in their current form, but prior to that, 14th Edition had a similar Regulation B.100 for conductors of AC metal conduit.

Para 3 (clearly permitting parallel cpc for armoured cables) was not present in BS 7671:2018, but came in at 17th Ed Amendment 1 (BS 7671:2018+A1:2011). It is interesting to consider, though, under what conditions a parallel cpc may or may not be useful (for example, whilst it would definitely be OK to consider it for faults downstream of the SWA+cpc combination, for buried SWA cables, where we have a fault line (or lines) to armour following severing of the cable, the parallel cpc may well be ineffective).

If you let me know, I can provide some more info on the bit you're interested in, expanding on the above.

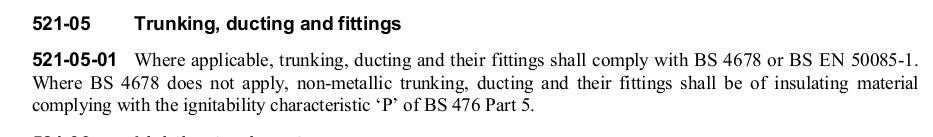

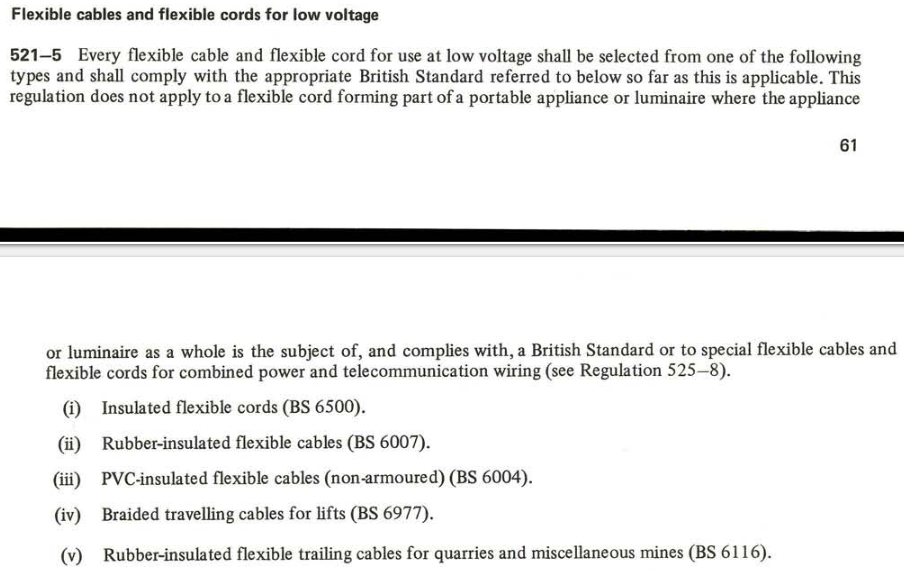

The library is in the IET building - between the Embankment and the strand in London. however, to save you the time you have 3 choices. Whcich did ou want, mechanical forces, trunking flammability or cable types - the same bit of the regs has been all of these over the last few editions.

Leaning heavily on the way UK copyright law allows reproduction of extracts of copyrighted documents for study or criticism, here is a chance to compare and to criticize the numbering schemes...

17th Edition

521.5 A.C. circuits: electromagnetic effects

521.5.1 Electromechanical stresses

Every conductor or cable shall have adequate strength and be so installed as to withstand the electromechanical

forces that may be caused by any current, including fault current, it may have to carry in service.

16th edition 2001 version

or 15th

It’s paragraphs 1 & 2 I’m interested in, specifically that “an appropriate protective conductor” should be contained within the same enclosure and that these conductors should be “collectively surrounded by ferromagnetic material”

Was it worded in the exact same way in both the 17th and 16th editions? I’d be very appreciative if you were able to tell me if it was still regulation 521.5.1 in both 16th and 17th, this might sound silly but what page number was it on in these editions.

I have a copy of the 17th A1 2011, I can see the wording hasn’t changed at all in any subsequent edition and remains regulation 521.5.1 to this day. I’m interested to see if this evolved at all from the 16th edition?

the exact reg numbers and page numbers would really help.

17th Edition BS 7671:2008

521.5.2 Ferromagnetic enclosures: electromagnetic effects

Single-core cables armoured with steel wire or steel tape shall not be used for an a.c. circuit. The conductors of an a.c. circuit installed in a ferromagnetic enclosure shall be arranged so that all line conductors and the neutral conductor, if any, and the appropriate protective conductor are contained in the same enclosure.

Where such conductors enter a ferrous enclosure, they shall be arranged such that the conductors are only collectively surrounded by ferrous material.

16th Edition 1991 (including BS 7671:1992) to 16th Edition BS 7671:2001+A2:2004

521-02 Cables for a.c. circuits - electromagnetic effects

521-02-01 Single-core cables armoured with steel wire or tape shall not be used for a.c. circuits. Conductors of a.c. circuits installed in ferromagnetic enclosures shall be arranged so that the conductors of all phases and the neutral conductor (if any) and the appropriate protective conductor of each circuit are contained in the same enclosure.

Where such conductors enter a ferrous enclosure they shall be arranged so that the conductors are not individually surrounded by a ferrous material, or other provision shall be made to prevent eddy (induced) currents.

15th Edition 1981

Cables for a.c. circuits - electromagnetic effects

521-8 Single-core cables armoured with steel wire or tape shall not be used for a.c. Conductors of a.c. circuits installed in ferrous enclosures shall be arranged so that the conductors of all phases and the neutral conductor (if any) are contained in the same enclosure. Where such conductors enter ferrous enclosures they shall be arranged so that the conductors are not separated by a ferrous material or provisions shall be made to prevent circulating eddy currents.

14th Edition (similar "topic" to cyan highlight)

B.100 Cables of a.c. circuits installed in steel conduit shall always be so bunched that the cables of all phases and the neutral conductor (if any) are contained in the same conduit.

So, it looks like "eddy currents" for cables entering enclosures came in with 15th Edition, but "all conductors of AC circuits being enclosed together when enclosed by ferrous metal" was a concept existing in 14th Edition (or perhaps earlier ... I haven't looked back any further). Hopefully this is what you're looking for, and that my highlights for 15th, 16th and 17th Editions are helpful?

That’s really helpful thank you! May I ask two questions? First of all do you know what page number 521.5.2 appeared in on in 2008 edition.

My second question, I had a feeling that around the 16th edition the requirements changed slightly to include the “appropriate protective conductor”. I’m just wondering why? Surely as the protective conductor is only carrying current under fault conditions and for a short period of time (assuming disconnection times are met), it seems unlikely that there would be any significant overheating in this time.

Im a best practice kind of guy so I don’t question the practice, but I’m interested in why the powers that be saw fit to include the protective conductor? Were there incidents.

Surely as the protective conductor is only carrying current under fault conditions and for a short period of time (assuming disconnection times are met), it seems unlikely that there would be any significant overheating in this time.

I suspect there's an idea that a conductor on the other side of a ferrous barrier has extra inductance - so the earth fault currents may be reduced (extending disconnection times etc)

- Andy.

There are two problems, one really is eddy currents (electric currents induced transformer-like along the length, parallel to the net current enclosed)

This sort of effect is just as serious on AWA or SWA, as in conduit and is the one where brass glands run hot... The second, and the one where the ferrous nature of the enclosure matters, is magnetic hysteresis losses, the periodic de and re magnetizing in the magnetic materials surrounding the enclosed wires, the lines of action forming of loops of magnetic field around the wires - i,e. at right angles to current flow, Split tube conduit and most SWA is not as badly affected by this as proper seam welded conduit the air gaps lower the round loop reluctance massively.

This reg is all about magnetic losses. Not currents. you could slice the steel conduit into short tubes or even washers and thread it on the wires, and still get the magnetic losses. The eddy current effects however would be stopped.

But it is often not clearly taught, and to pour water on troubled oil, some sloppy text books from the last century, by folk who should know better referred to the magnetic case as 'eddy current loss' when really it is a completely separate and orthogonal effect, and the error seems to perpetuate.

When serious fault currents are involved the magnetic material tends to saturate nearest the wire, and the losses tend to stop rising any more beyond a certain point. (in other words the series inductance, and its loss tangent, fall away)

Mike.

First of all do you know what page number 521.5.2 appeared in on in 2008 edition.

97

My second question, I had a feeling that around the 16th edition the requirements changed slightly to include the “appropriate protective conductor”. I’m just wondering why? Surely as the protective conductor is only carrying current under fault conditions and for a short period of time (assuming disconnection times are met), it seems unlikely that there would be any significant overheating in this time.

I'm not 100 % sure, but there is clearly an issue with inductance etc. ... Have a look at what is now (and in 17th Ed) 543.6.1.

First of all do you know what page number 521.5.2 appeared in on in 2008 edition.

97

My second question, I had a feeling that around the 16th edition the requirements changed slightly to include the “appropriate protective conductor”. I’m just wondering why? Surely as the protective conductor is only carrying current under fault conditions and for a short period of time (assuming disconnection times are met), it seems unlikely that there would be any significant overheating in this time.

I'm not 100 % sure, but there is clearly an issue with inductance etc. ... Have a look at what is now (and in 17th Ed) 543.6.1.

Well… first of all doing some very quick studying in magnetic losses… and secondly referring to 543.6.1 and making perhaps a sensible deduction… where a protective conductor is not incorporated in the same wiring system as the live conductors or in their immediate proximity or separated by ferrous material, this may cause magnetic losses which could affect disconnection times in much the same way as circuit length affects disconnection times.

is that a close enough for rock and roll just of things here?

Threading a current through a block of magnetic material raises the inductance of the wire, for sure,and if the 'mu' value and the geometry of the surrounding magnetic material , in this case a cylinder, is known, then the inductance per inch of conduit or whatever can be easily deduced as the one turn limit of the toroid core problem.

But note that the magnetic properties of conduit steel are not well specified, and any mu value in the range from maybe 500 (nut and bolt steel) up to perhaps 30,000 for magnetically optimized steels is possible, At the same time the saturation characteristics are pretty fixed regardless of steel blend, at around Tesla RMS, so one can work out the lowest dV/dt for which the steel appears to increase the inductance, even if the inductance for conditions less than this is hard to deduce.

At 50Hz you need several feet of conduit to become noticeable, and that is assuming conduit made of transformer steel (such as the stuff described around page 30 in that link),

regards Mike

PS example BS 4568 conduit dimensions are 20 or 25mm OD, and 1,6mm wall thickness.

(magnetic path length of pi * 18.4mm for the 20mm, and pi* 23.4mm for the 25mm, magnetic area 1.6mm* length)

Let as assume the 2 extremes - a high mu steel of say 20,000

a 1m length of 20mm conduit would add 20000* 4π × 10-7 H/m* 0.016m^2/ (0.01844*pi) = 0.006956522 H

(6.9milli Henries.)

and a low mu case of 500.

then 0.000173913H or about 170 microHenries.

Then we should consider the saturation of that core - in the high mu case about 20A/m - and given the magnetic path is only about 50mm long that saturation occurs at around one amp in the wire. For a conduit of low mu steel, we an expect more like 40A.

For long runs of conduit the inductance becomes worth considering for its effect on low current Zs readings - after all at 50Hz 1millihentry is 1/3 of an ohm (more or less).

All likely fault currents will not see the full inductance or anything like - as shown above, somewhere between 1A and 40A the steel will saturate instead, and the extra inductance 'switches off'

For unknown steels it is fairly safe to assume the loss impedance is about 10% of the inductive impedance at most, and usually quite a bit less. - so you can imagine the effect of threading conduit over the wire not just to add inductance, but also to transformer couple into a loss resistor.

Mike.

is that a close enough for rock and roll just of things here?

Works for me in this case.

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site