As is well known, the nominal or declared voltage of UK low voltage mains was reduced from 240 volts down to 230 volts, some years ago. Nothing much actually changed though and the measured voltage still tends to be 240 volts most of the time in most places.

But what is the design voltage of mains voltage incandescent lamps for the UK market ? is it 230 volts or 240 volts. Is the light output and service life measured at 230 volts or at 240 ?

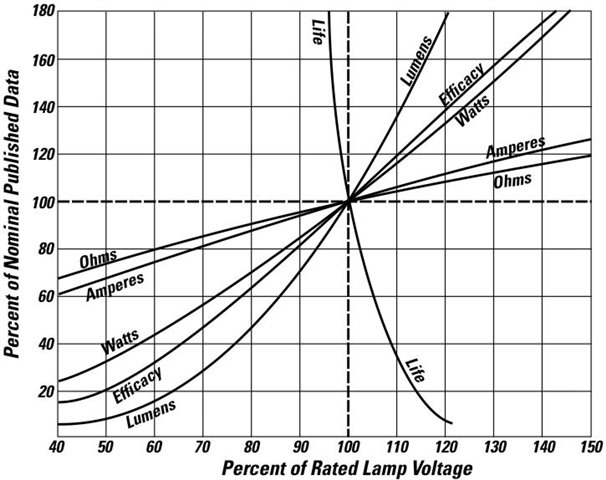

If a lamp designed for 230 volts is burnt at 240 volts the life will be significantly reduced.

If a lamp designed for 240 volts is run from an actual 230 volt supply, then the light output will be significantly reduced.

Incandescent lamps are now much less used, but there is still a substantial market via a number of loopholes. Traffic signals still use incandescent lamps.