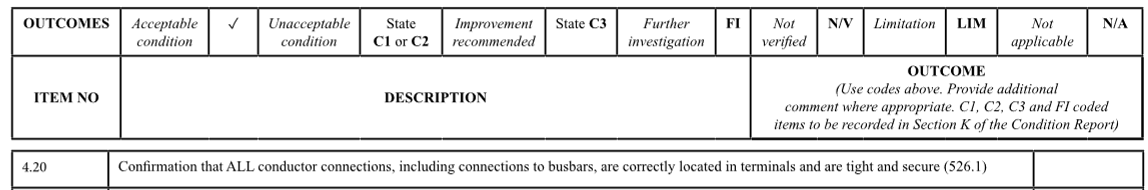

I just wondered how others might view this?

Easy just to tick without really thinking about it, but how could it be determined that conductors are "tight"? Does it mean you just look, give a wee tug or do you burst a blood vessel with an extra twist way beyond manufacturers torque setting?