Hi,

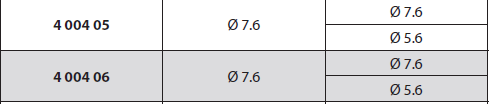

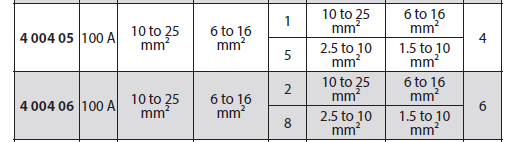

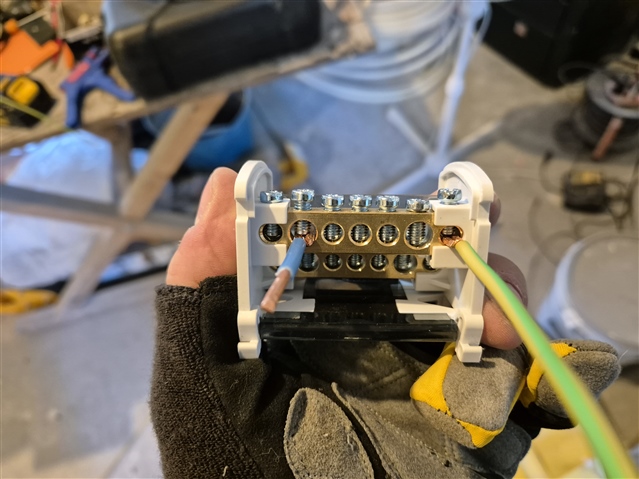

I need to fit a 3-phase distribution block, and the closest candidate has two types of inputs—input (two) and output (six). The input is 7.6mm2, and the output is 5.6mm2, and one of the inputs can be used as an output. I only use rigid conductors of 1.5-6mm2 in the house - the lights are 1.5, the majority is 2.5, power-hungry is 4mm2, and one fat transit is 6mm2. Depending on the breaker's possible load, I use 4 or 6mm2 inside the wiring closet to pass between the power-hungry groups. I don't use

Within this paradigm, I would like to use 6mm2 as an input and possibly 4mm2 as an output for the distribution block. But, following Legrand's user manual, the 7.6mm2 should accommodate 10 to 25 mm, and I am falling one step short of matching 6mm2. IMHO, I can use aluminum pressed ferrule to increase the solid wire size - the connection surface must be enough to avoid any dangerous situations. What is your take on it?

Regards