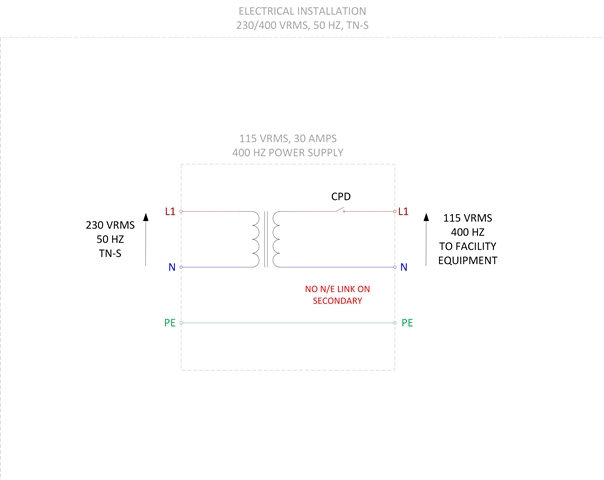

On one of our facilities we have come across a 400 Hz, 115 Vrms power supply whose secondary side neutral does not appear to be connected to facility earth and is effectively floating. Approx. 50 Vrms Neutral to GND is observed on the secondary side of the power supply unit.

Some observations are:

- The power supply units are installed "fixed" within the electrical installation and wired in permanently (not portable).

- The PSU is class I equipment as is the downstream equipment connected to it

- The PSU chassis is connected to PE on the incoming supply

- The PSU output includes a thermal magnetic circuit breaker, implying the OEM intends for ADS to be used as the chosen method of protection against electric shock

- We can't see any OEM facility inside the power supply for the Neutral and PE to be connected on the secondary side

- There doesn't appear to be a route for a "Line" to "Exposed Conductive Part" fault currents to make their way back to the secondary side of the PSU neutral and so the thermal magnetic breaker and ADS is questionable

- There is no insulation monitoring installed on the secondary side

- We have gone back to the OEM to ask how their system design meets the intent of the wiring regulations for protection against electric shock but we are not getting an answer

Does anyone have any thoughts on why the OEM might have taken this approach or any specific regulation requirements we need to be cognisant of before proceeding further? My initial thoughts are that we need to introduce another neutral to PE reference link on the output side of the PSU for the purpose of ADS and also to prevent issues with floating neutral voltages downstream.

Thanks,

Richard