Hello,

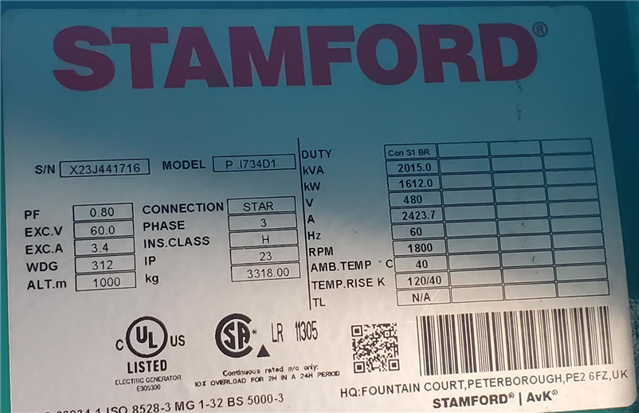

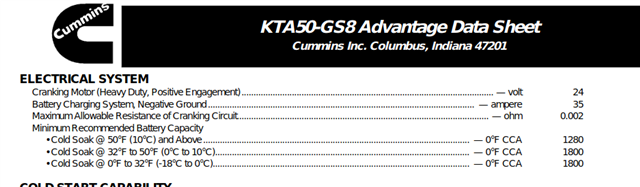

I need to replace an original cables which are too short from an industrial generator (Stamford PI734D1) to batteries Cummins 12V 1400A 220Ah (0416-0439) connected in series so 24V

Sorry but my knowledge and experience on this subject is very limited. The cables supplied by the manufacturer are AWM 3340 or 3374 150degC 600V

My question is whether H07 or Coil and Lead could possibly be used as a replacement for the original ones? What size would be sufficient for this scenario?

The batteries will be standing about 4 meters away from the generator.