Hi all,

Apologies for the click bait title.

A MCB has failed within a control panel, this MCB is now obsolete with no direct replacement, as is the manufacturer of the control panel who certified this control panel to BS-61439-1.

My employer thinks that a C100A MCB is a C100A MCB, however apparently not in the eyes of the reg 536.4.203

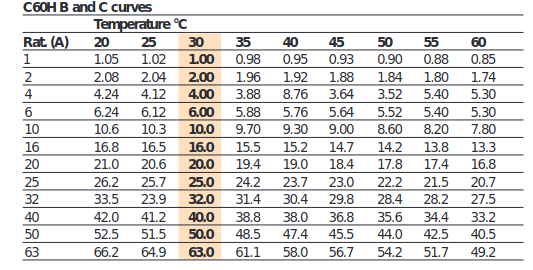

The panel doesn't appear to do anything special and doesn't feed anything of any real consequence. I am trying to evaluate whether I can swap for a Schneider C100A MCB which seems to have pretty close characteristics according to data sheet and operating curves.

I have came across this helpful IET article on the subject Myth Busters #7 - Out with the old, in with the new? (theiet.org), however I would like to know what specifically do I need to assess, and what is the real risk?

Am I overthinking this?

Thanks