Hi all,

I’ve been trying to settle a difference of opinion and looking for advice.

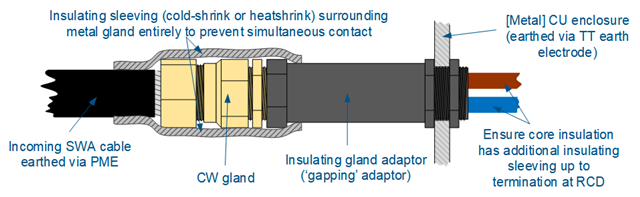

we have several supplies fed in SWA, they have all been glanded off with a CW gland into the DB. At the load end, the armouring has been taped up and a plastic stuffing gland has been used where it enters metal EV Chargers, its been done deliberately to isolate the earth to the chargers.

My colleague and I think this is poor practice and think an isolating gland should have been fitted or the armoured terminated into a plastic enclosure prior to entering the charger. the below regulations are what we believe are contravened.

Regulation 134.1.1Good workmanship by competent persons or persons under their supervision and proper materials shall be used in the erection of the electrical installation.

regulation 526.8 Cores of sheathed cables from which the sheath has been removed and non-sheathed cables at the

termination of conduit, ducting or trunking shall be enclosed as required by Regulation 526.5.

Our colleagues think we are incorrect, yet have conceded that the use of a stuffing gland isn’t to manufacturers instructions and agree that the stuffing gland isn’t supporting the cable like a SWA glad would by clamping the armour.

what is everyone’s view on here?