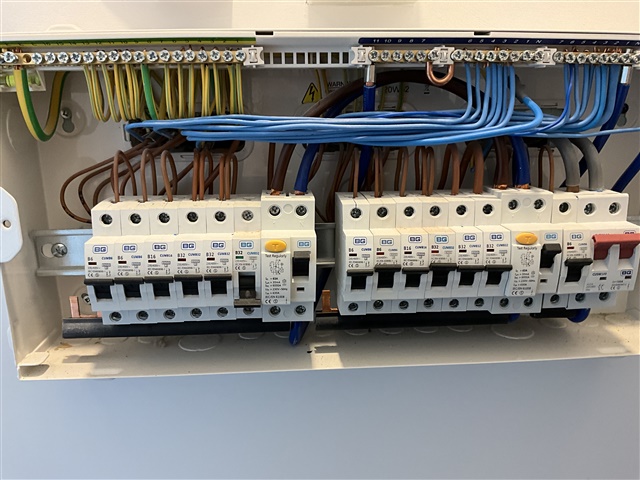

This consumer unit is installed directly on to an internal stud wall. Note the cables coming through the rear. Makes a neat job. However, following a fire in a consumer unit in a relatively new house quite a number of years ago, I have always advised that when making cable entry via the rear, holes should be as tight as possible and/or intumescent sealing arrangement applied. In the case of that incident, the fire didn’t spread but smoke entered the stud and made its way out through an aerial socket in a bedroom of the floor immediately above the consumer unit, which was located in the ground floor cloak room. Volumes of choking smoke entered the bedroom where a baby was sleeping. It was quite some time before the smoke detector in the landing operated to wake the parents, narrowly missing a tragedy.

The photo shows very common wiring practice which is likely present in many domestic situations.