I need some advice about running power to flower beds and a shed using 2.5mm NYY-J cable and whether it complies with BS.

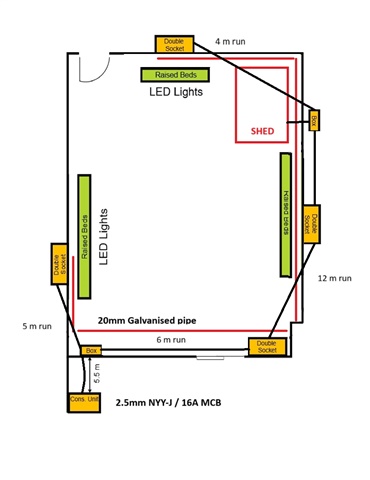

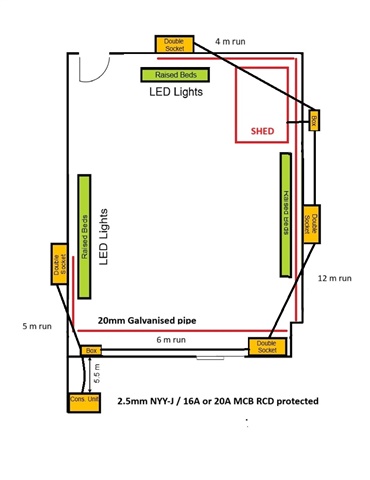

The cable will feed from the consumer unit using a 16A MCB to an outside connection box to feed both sides of plants (as diagram provided).

The cable size and MCB were chosen based my needs and the limited power to be drawnThe cable will not be buried but will run along the perimeter of my fence on top of a 20mm pipe (not plastic conduit) secured either with plastic or metal cable ties.

The pipe will secured the concrete fence posts150mm above the ground heavy-duty saddles.

Each bed will have a double socket IP only for LED.

The power to the shed be fed from second connection box to double socket.

I have posted this to an electrical forum, but people are discussing different things and not my specific question.

This is why tried the IET forum, so competent people/engineers can give me advice. If the above-mentioned setup sounds good or not, please reply.

Thank you advance.