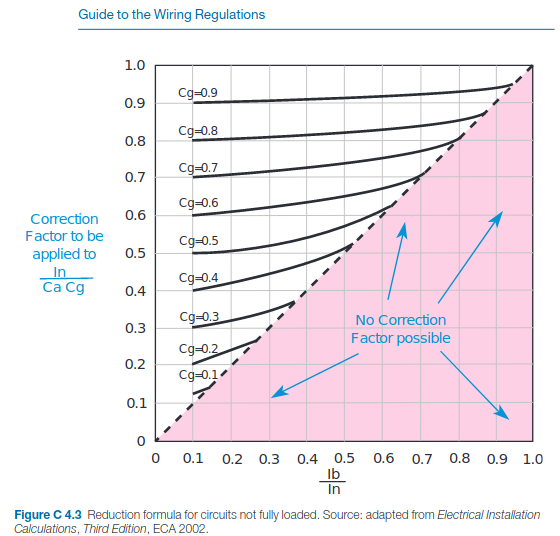

Consumer unit & gas ch combi to be installed in a brick cupboard (1200 x 1200 x 2500, with concrete ceiling ) just off the kitchen. The only cable route out is up over the door and through the brick wall to the main house. I've decided on perforated tray 225mm wide for good spacing which will be mounted 10mm from the wall. I'm comfortable with the cable selection for the 6 circuits on the tray and believe I can negate the grouping factor as per note 2 for table 4C1.

For example; the kitchen ring final ; design current of 30a, will require 6mm T&E through the hot area ( I've called the ambient temp 45 degrees) but crucially I'd like to reduce this to 4mm once I'm in the room itself and terminating to the sockets Similarly I'd intend to install the lighting cicuits through the utility cupboard and 2 metres beyond to a common junction box at standard ambient where I would reduce to 1.5mm for distribution & terminations. Is this a viable startegy and/ or am I missing a regulations prohibition?

Thanks for any comments,

Pete Murphy