Hi,

I've noticed recently that lift companies tend to use SY cable for the supply cable from the Mian isolator (provided by main MEP contractor under BS7671) to the lift control panel main intake connection of the lift

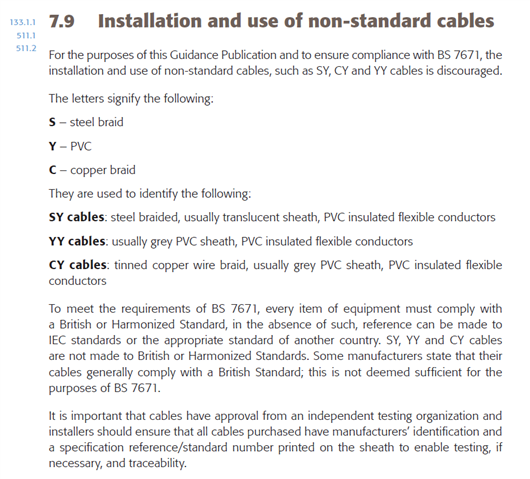

I know Lifts are not covered by BS7671, but I'm aware that these cable types are designed for use in Control environments and are discouraged in BS7671 for power circuits/Fixed installations

when questioned lift companies just issue data sheets for the said cable, spouting VDE compliance, although they are not manufactured to any manufacturing standard, how do they certify the installation when every way you look points to them not to be used as power cables? even if in lift installations?

:The cable manufacturers even state on their data sheet they are "control cables" with mech protection

Regards