We are providing some lighting dimmer panels (they also provide hard power and switched power - configurable on a per-channel basis) for a theatre installation. All the dimmer outputs are 10A single phase circuits and the dimmer has a 3-phase supply.

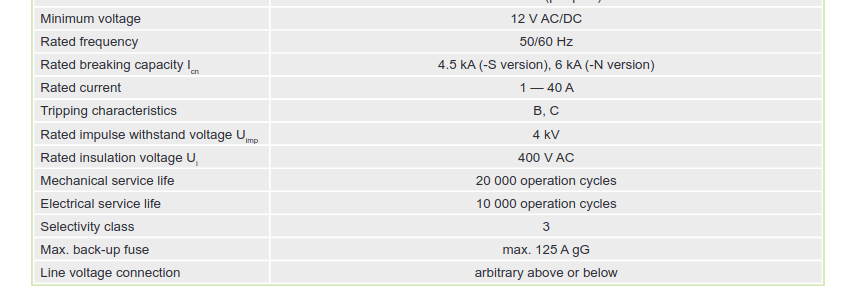

The electrical consultant has stated that the worst case PFC for a fault at the dimmer outputs is approx 9kA - presumably this is on a bolted phase-phase short.. The dimmers are provided with 6kA breaking capacity Type C 10A MCBs (to EN 60898) with neutral disconnect for their output circuits. The consultant is saying that these must be replaced with 10kA devices. This of course is not a simple matter as the product is CE/UKCA marked and such a modification would likely require a re-certification by the manufacturer with significant cost and time impacts. Clearly we can't simply swap the devices over ourselves and the manufacturers are not keen to do it either.

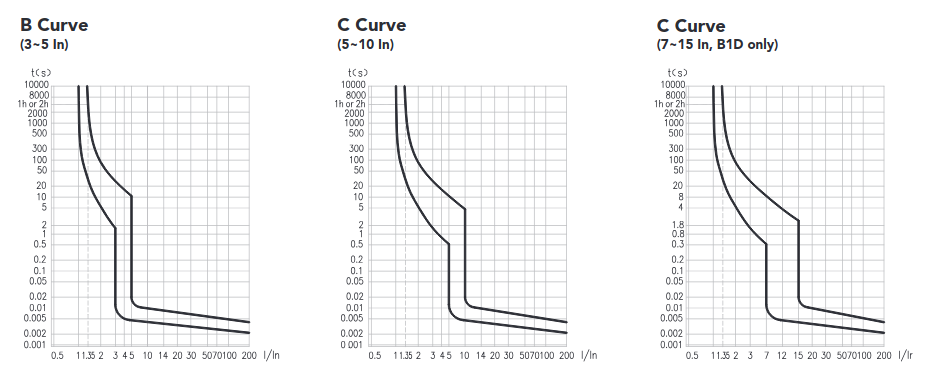

The upstream protective device is a 80A Type D MCB to EN60947-2 (fixed - non adjustable), and has a breaking capacity of 10kA. Looking at the trip time curve for that device once you get to around 800A you hit the 'instantaneous' region. Likewise for the dimmer MCB once you hit 100A you are in the 'instantaneous' region.

My argument is that if there If there is a fault current of 1kA-6kA, you're likely to be in to a race between the 80A and 10A breakers where you can't predict the winner anyway, and in the worst case of a fault current >6kA and the 10A MCB welds shut the 80A MCB will open within it's fastest possible operation anyway (sub 0.1s).

Also, on a 4mm2 CSA output cable by my calculations once you get to about 8m of cable the worst case fault current is dropped to 6kA anyway.

434.5.1 provides for a higher breaking capacity device upstream to provide protection for a downstream device, although energy let-through needs to be considered.

Is my logic correct or flawed, and is there anything else we would need to do to determine if the configuration decsribed above is compliant? We know the very high fault current would be an edge-case in terms of likelihood but the electrical consultant is very particular on this project.

NB - We have looked at alternative manufacturers of similar products (there aren't many) and they all use 6kA MCBs. There is a 'bigger brother' product with higher breaking capacity which won't fit physically and would have a significant cost uplift that I expect will not be feasible.

Thanks in advance.

Jason.