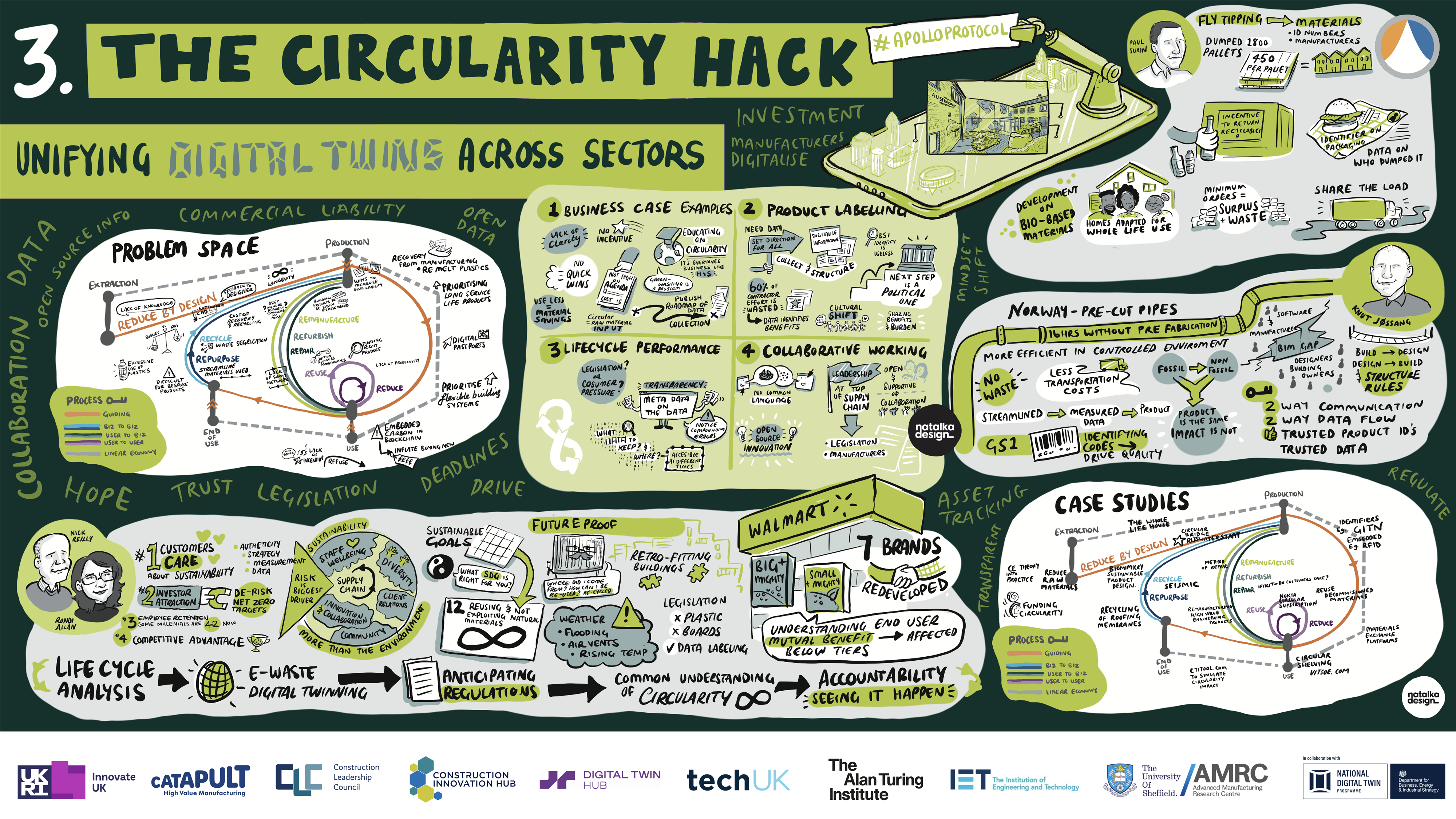

Here’s a summary of some of the outcomes of our third Apollo Protocol Hack and information about how you can join the next one.

We’re three hacks in, three themes explored. What strikes me most about attending and participating in these interactive events is how much we need to learn from each other.

When we fleshed out each theme in the Apollo Protocol white paper last year, we knew that there were opportunities for learning, but we’ve learned so much more about the value of cross-sector understanding of the major challenges facing manufacturing and the built environment today.

By bringing together professionals with a keen interest in a theme, the practitioners working on the coal face and tech specialists who understand the value of data, we benefit from a deep and revelatory understanding of what is actually happening and can begin to explore how it might change.

Extract from ‘The Apollo Protocol: unifying digital twins across sectors’ White Paper

Why do contractors bury bricks?

A great example of this was the discussion we had about the massive waste of materials in housebuilding in the online hack session.

Contractors routinely dump bricks on site – the gardens of new build housing are often plagued with buried left over materials. Why does this happen?

- Firstly, many products are routinely over-ordered by 10% to allow for breakage and wastage. Why? Because delays to works are penalised more than waste – it’s a simple risk calculation.

- What is more, unused pallets of bricks are more expensive to transport to another site (where they may not be the right specification anyway) than to dump in a hole you’ve probably already dug, or at the side of the road.

- Some calculations suggest there may be as many as 2,500 bricks dumped per site – equivalent to a third of the bricks needed for a standard home. Brick manufacturing is also a very energy hungry process..

- We are dealing with a very tightly controlled restrictive market. Merchants and distributors protect their margins and are resistant to change, and contractors and subcontractors’ margins give them very little room to manoeuvre. There is no motivation to look at the problem because as far as they are concerned, it isn’t one.

What is Circularity?

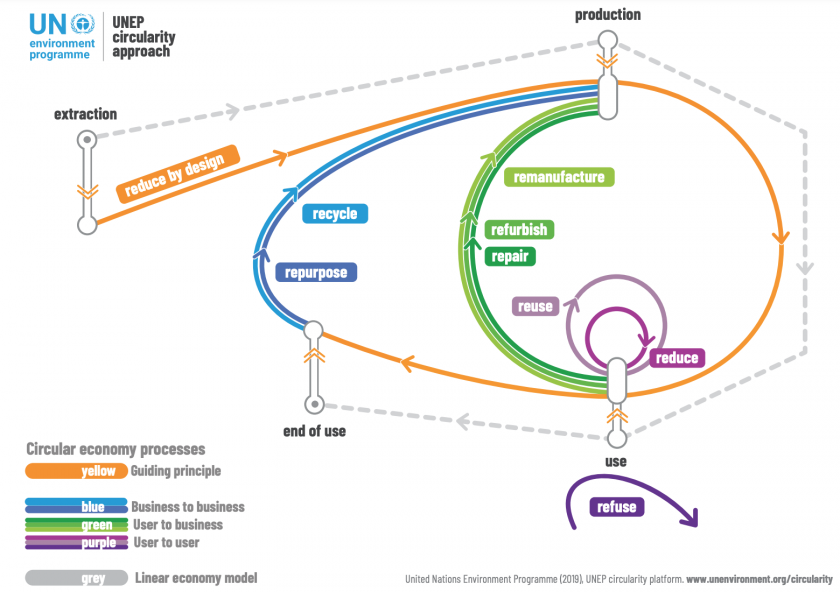

Circularity, or the Circular Economy, is a more complex topic than many recognised. With a limited understanding one might believe that the most important concept is recycling, but recycling is in fact the last resort, the least-best option.

A key principle of the circular economy is to circulate products and materials at their highest value. This way the intrinsic value of products and materials are retained within a circular system.

The UN Environment Programme produced a diagram to explain what retaining the highest value means. It sets out a hierarchy of ‘value retention loops’ which describe ways in which value can be retained rather than falling out of the cycle (into the appropriately coffin-shaped linear process we currently use).

UN Environment Programme circularity approach

The orange line is the guiding principle of the circular economy: Reduce by Design. Products and services should always be designed to use fewer materials in the first place. We then have three User-to-User based value retention loops (purple), a series of (green) User to Producer value retention loops and finally two End of Use value retention loops (blue).

To retain the value in products and materials, we need to use fewer of them, then use them for longer, be able to fix them when they break, all to eliminate waste, energy and cost.

Barriers to Circularity

Cost, then, isn’t going to be the only barrier to circularity; things are more complicated. In March 2022 the IET Built Environment Panel Plain Language Guide Editorial Board identified four barriers to implementing a circular economy:

- Commercial preference for building new, with new materials and on new sites – there is no desire to reuse materials as it is cheaper and lower risk to use new ones.

- Lack of information about the products in built assets – in other words, not knowing what is there, that can be reused.

- Lack of supply chain transparency more generally – the tendency is to withhold information rather than share it, and

- Lack of an established market for the reuse of products and materials – so that it becomes commercially attractive.

Enabling circularity – which is essential to every international multilateral agreement on sustainability – depends upon markets, costs, transparency and data. With that in mind, participation in a circular economy cannot only depend upon the goodwill of businesses. It must be feasible.

The Business Case

Nick Reilly and Rondi Allan of Sustainable X joined us to outline the business case for circularity from their perspective as sustainability consultants. We were keen to welcome them to the hack because Rondi is from a product background, whereas Nick is from contracting. Their fascinating examples illustrated the value of cross sector collaboration.

Rondi Allan and Nick Reilly introduce the business case for circularity

Nick and Rondi identified five key elements to the business case:

- Customer Demand: both business to business and consumer.

- Investor Attraction: businesses are increasingly required to demonstrate sustainability credentials to attract investors.

- Employee Retention is improved in a company that addresses these issues, particularly in the white-collar market.

- Competitive Advantage: for companies seeing to learn from other sectors and differentiate, and most importantly,

- Risk Management. Cynics about sustainability might not care about the ethics but they will be concerned about losing customers, investors, or the best people from their organisation. As Extended Producer Responsibility hits all products, all companies are at risk unless they take control of assets at the end of life.

Nick and Rondi then led us in a group activity exploring problems and solutions around the examples they shared which led to some in depth discussions focused on the commercial opportunities and challenges. For example, should we change the business case by marketing products with a better circularity proposition as ‘premium products’, or should we tighten up the waste regulations, or procurement or maintenance processes, or do we need a more transformative solution?

The Role of Digital Twins, Data and Information Management

Data is key to understanding what products and materials you have. Knut Jøssang of Pipelife Norway and Alex Small of Tata Steel Europe, provided us with two manufacturers’ perspectives on the challenges.

Knut Jøssang of Pipelife Norway

Knut spoke to us on the in-person hack about the company’s attempts to introduce prefabricated plastic piping systems on site and pipes with recycled and renewable content. Environmental Product Declaration systems don’t make transitioning to fossil-free pipework any easier, and will only work if they are machine readable, i.e. digitised. Ultimately Knut argued that the only way to make monitored changes are if trusted and traceable data is available and we improve communication between the manufacturers, logistics and distributor side of the ‘BIM-gap’ and the designers, contractors and building owners.

Alex challenged our online hack audience to compare the manufacturer-built environment data interface with how information is shared across the travel sector. With implemented rules and standards via a common platform, travel apps and services can use full interoperability to communicate to customers information on hotels, flights and more. In the built environment none of that interoperability exists. Alex kindly shared with us some of the work Tata Steel are doing in this space and details of a collaborative venture which is not yet in the public domain but might be the first step towards making interoperability of product data possible.

Manufacturers hold the key to information management in the built environment, I believe. If they can work to common standards and produce the structured data about their products, the whole supply chain through designers, contractors and asset owners will benefit. Structured data to common standards enables unique product identifiers. This would make a foundation on which circularity data and metrics could rest. But manufacturers can only do that with the support of the rest of us as individuals and organisations.

Whilst the need for standardisation and digitisation was widely recognised by the hack audience, the other theme revisited was education. A lack of understanding of circularity itself, digital twins and information management across our industries is recognised, and we need to invest in educating ourselves on the fundamentals.

Use Case Examples – identifying what is possible

Hack participants once again identified challenges, use cases and case studies for the use of information management and digital twins in the field of circularity. Here are a few examples:

- Data Standards are essential, for identifiers, labelling, traceability, measurement parameters and more. Does industry require a government mandate for product data and digital product passports?

- Manufacturers need to implement digitisation and be supported by distributors and their customers to support proper data flow through the life of built assets and increasing digitalisation in the construction sector. Could we extend Product Lifecycle Management (PLM) beyond the manufacturer?

- Servitisation would be a means of decoupling growth and resource use, maintaining the relationship between manufacturer and user. This is an example of where construction can learn from the automotive and other industries.

- Material Exchange Platforms could reduce waste. The Supply Chain Sustainability School has a map of UK ones, but there are also many local initiatives.

- Procurement methods need to modernise so they are not so price dependent and become collaborative. One option might be extending the principles of Project 13 from infrastructure delivery into the supply chain for construction and manufacturing.

- MTC’s IGNITE project (an integrated intelligent digital tendering system) has potential to transform the supply chain to better serve a digital economy and track products, materials and emissions.

- We need to reform the project handover process so that an appropriate project specific database can be maintained by the client and passed on with the built asset.

- Maintenance prospects could be improved by coupling maintenance and construction responsibilities. Incorporating maintenance contracts into products can empower customers to retain products longer term.

Listen to the Apollo Forum Podcast

If you’re interested to learn more about what we discussed, why not listen to the podcast episode about this hack? It includes interviews with speakers and conversations with participants.

If you’re interested to learn more about what we discussed, why not listen to the podcast episode about this hack? It includes interviews with speakers and conversations with participants.

Listen here:

https://soundcloud.com/apollo-forum/circularity-hack-podcast

Follow the podcast so you get notifications when we publish new episodes.

Join the Apollo Forum Hacks

Our next hack will be looking at Human Capital, what digital skills are and how we can work together to educate our sectors and get the resources we need.

If you are interested in

- becoming better informed about digital requirements for the future,

- helping your staff to participate in a future digitised company,

- recruiting people with digital skills and even

- understanding what digital skills are,

we’d love you to join us at these free, interactive events.

In person:

The Human Capital Hack at IET London Savoy Place, 9.30-4 on 9 February

On Zoom:

The Human Capital Hack Online 1-4pm 16 February

About the Apollo Protocol

The Apollo Protocol is an initiative to unlock the benefits of digital twins between the built environment and manufacturing sectors, supported by the technology sector.

Read more in our white paper The Apollo Protocol: unifying digital twins across sectors

The initiative is supported by:

- The Department for Business, Energy and Industrial Strategy (BEIS)

- Innovate UK

- The Institute of Engineering and Technology (IET),

- The Construction Leadership Council (CLC),

- The University of Sheffield Advanced Manufacturing Research Centre (AMRC),

- The High Value Manufacturing (HVM) Catapult,

- The Construction Innovation Hub,

- The Digital Twin Hub,

- techUK and

- the Alan Turing Institute.