In an era of technological advancement and complexity, the integration of Quality 4.0 principles into programme and project management has emerged as a transformative approach. Quality 4.0, a fusion of traditional quality management methodologies with Industry 4.0 technologies, offers a new paradigm for managing complex programmes and projects. This article explores and gives an overview of how Quality 4.0 can effectively drive improved programme and project management, leading to enhanced efficiency, accuracy, stakeholder satisfaction, and overall project success. Through a summary review of the literature, relevant case studies, and practitioner insights gained from discussions with peers, this article illustrates the potential impact of Quality 4.0 on programme and project management.

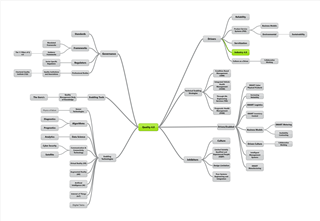

Programme and project management are critical functions for organizations aiming to deliver value, achieve strategic goals, and meet customer expectations. However, the landscape of project management has, and continues to, evolve significantly with the advent of Industry 4.0 technologies. This continues to prompt the need for innovative approaches to ensure success. Quality 4.0, a concept that integrates quality principles with advanced technologies, presents an effective driver for improving programme and project management practices. This article delves into the fundamental principles of Quality 4.0 and examines how its application can bring about tangible benefits to programme and project management processes. An overview of the scope of Quality 4.0 is illustrated in Figure 1.

Figure 1: Defining the Scope, Drivers, Context and Applications of Quality 4.0

The Quality 4.0 principles build upon the foundation of traditional quality management methodologies which include Total Quality Management (TQM), Lean, Six Sigma, and more. These principles are identified as being:

(i) Customer Focus: Quality 4.0 places the customer at the centre, aligning with the project management goal of delivering products and services that meet or exceed stakeholder expectations. By leveraging data analytics and feedback mechanisms, project managers can better understand customer needs and preferences, leading to more successful project outcomes.

(ii) Data-Driven Decision-Making: Quality 4.0 emphasizes the use of data for informed decision-making. In project management, data from various sources such as sensors, historical records, and real-time updates can provide valuable insights. This links to the 'Digital Twin' application which is gathering increasing traction in the world of project management relative to complex engineering projects (marine, automotive, aerospace, military etc). This data-driven approach enhances project managers' ability to make timely and accurate decisions, reducing risks and improving project performance.

(iii) Continuous Improvement: Quality 4.0 promotes a culture of continuous improvement, akin to the iterative nature of project management. Lessons learned from past projects, data analysis, and feedback mechanisms contribute to refining project processes and methodologies for future endeavours.

(iv) Employee Engagement: Engaged teams are essential for project success. Quality 4.0 principles advocate for involving employees at all levels in quality improvement efforts. Engaged teams are more likely to collaborate effectively, share insights, and contribute to innovative solutions, all of which are crucial in programme and project management.

(v) Process Optimization: Process optimization aligns with the project management objective of efficient resource utilization. Quality 4.0 technologies such as AI and automation enable the streamlining of project workflows, reducing manual interventions and enhancing overall efficiency.

Integration of Quality 4.0 in Programme and Project Management

Quality 4.0's integration into programme and project management is a strategic move that harnesses the capabilities of modern technologies to drive success. Several key areas highlight the effectiveness of this integration. The collection and analysis of data from diverse sources enable project managers to make informed decisions during the planning phase. Real-time data from IoT devices can provide insights into resource availability, potential bottlenecks, and risks. This information informs project plans, leading to more accurate estimations and realistic timelines.

Quality 4.0 technologies facilitate real-time monitoring of project progress and performance. IoT sensors and data analytics platforms provide project managers with constant updates, enabling them to identify deviations from the plan and take corrective actions promptly.

The predictive analytics capabilities of Quality 4.0 can also significantly enhance risk management. By analysing historical data and identifying patterns, AI algorithms can forecast potential risks and their impacts enabling project managers to implement proactive mitigation strategies, reducing the likelihood of risks materializing into issues.

Quality 4.0 also enables and promotes proactive collaboration among project teams, stakeholders, and even across geographies. Cloud-based collaboration platforms in use today facilitate seamless communication, document sharing, and real-time updates. This interconnectedness enhances transparency, reduces misunderstandings, and fosters a culture of open communication.

Thus the integration of Quality 4.0 principles enables project managers to optimize resource allocation. The use of AI-driven algorithms analyse historical project data to determine the most efficient distribution of resources and accurate resource 'smoothing', minimizing waste and ensuring optimal utilization.

The benefits of Quality 4.0 in Programme and Project Management:

The incorporation of Quality 4.0 principles into programme and project management yields a multitude of benefits. Typically these can be:

(i) Improved Decision-Making: Data-driven decision-making allows project managers to base their actions on objective insights rather than intuition. This leads to better choices in resource allocation, risk mitigation, and overall project direction.

(ii) Enhanced Efficiency: The automation and optimization capabilities of Quality 4.0 reduce manual interventions, streamline processes, and eliminate redundant tasks. This results in shorter project cycles, reduced costs, and improved overall efficiency.

(iii) Higher Accuracy: Accurate estimations, resource allocation, and risk assessments are critical for project success. Quality 4.0's data-driven approach enhances the accuracy of these aspects, reducing the likelihood of budget overruns and missed deadlines.

(iv) Proactive Risk Management: Quality 4.0's predictive analytics empowers project managers to identify and address potential risks before they escalate. This proactive approach ensures smoother project execution and fewer unexpected setbacks.

(v) Stakeholder Satisfaction: Ultimately, the successful implementation of projects aligns with stakeholder satisfaction. By delivering projects on time, within budget, and meeting quality expectations, project managers can enhance stakeholder relationships and build trust.

Case Studies

Real-world examples demonstrate the tangible impact of Quality 4.0 on programme and project management. Whilst Quality 4.0 is well practiced in the manufacture of complex engineering projects, it may yet to appear in other sectors. Typical examples of teh use of Quality 4.0 (and the emerging Quality 5.0) can be found in the following:

- Automotive Industry: Leading automobile manufacturers incorporate Quality 4.0 principles into their product development processes. IoT sensors embedded in prototypes provided real-time data on performance metrics. This enables early identification of design flaws, reducing the need for extensive design iterations and resulting in a higher-quality final product. Augmented reality is often applied to such processes within the design processes within the sector. For example, the engineering design team can 'journey' through the lubrication system of the engine and transmission to validate design performance.

The author has personal experience in this field gained from support of F1 Racing. In the sport the race car is actually a test bed for technology which if proven, eventually is used in mass production of cars which we all drive, Typically, such performance parameters and efficiency in body, transmission and engine design, and safety performance are all captured and informed by the application of Quality 4.0 strategies. In the car, sensors transmit telemetry to the pit lane detailing real time performance. This is then 'live' streamed to the team HQ and engineering departments where design modification and manufacturing commences relative to identified improvement initiatives which are then ready for the next race of the season.

- Construction Sector: It can be seen that some major construction companies are adopting Quality 4.0 practices for large-scale infrastructure projects (e.g. Nuclear Fusion and Small Modular Reactors). By leveraging predictive analytics, they optimized resource allocation, reducing cost overruns and project delays. This approach leads to improved profitability and increased client satisfaction.

Challenges and Considerations

Whilst the benefits of integrating Quality 4.0 principles into programme and project management are evident, challenges must be acknowledged:

(i) Data Privacy and Security: The collection and utilization of data raise concerns about privacy and security. Organizations must implement robust data protection measures to ensure compliance with regulations and safeguard sensitive information.

(ii) Integration Complexity: Integrating Quality 4.0 technologies into existing project management processes requires careful planning and execution. Ensuring interoperability between different systems and platforms is essential for seamless implementation.

(iii) Skill Development: Adopting Quality 4.0 practices demands a workforce with the skills to leverage advanced technologies effectively. Organizations must invest in training and development to equip their teams with the necessary expertise.

So what about the Future Direction for Quality 4.0

The author suggests that as technology continues to advance, the potential of Quality 4.0 in programme and project management is poised to grow. Further integration of AI, machine learning, and other emerging technologies will enhance the capabilities of project managers to deliver successful outcomes.

Quality 4.0 offers a powerful framework for improving programme and project management processes. By combining traditional quality management principles with Industry 4.0 technologies, organizations can achieve enhanced efficiency, accuracy, stakeholder satisfaction, and project success. Embracing the principles of Quality 4.0 positions project managers to navigate the complexities of the modern business landscape and drive improved programme and project management practices.